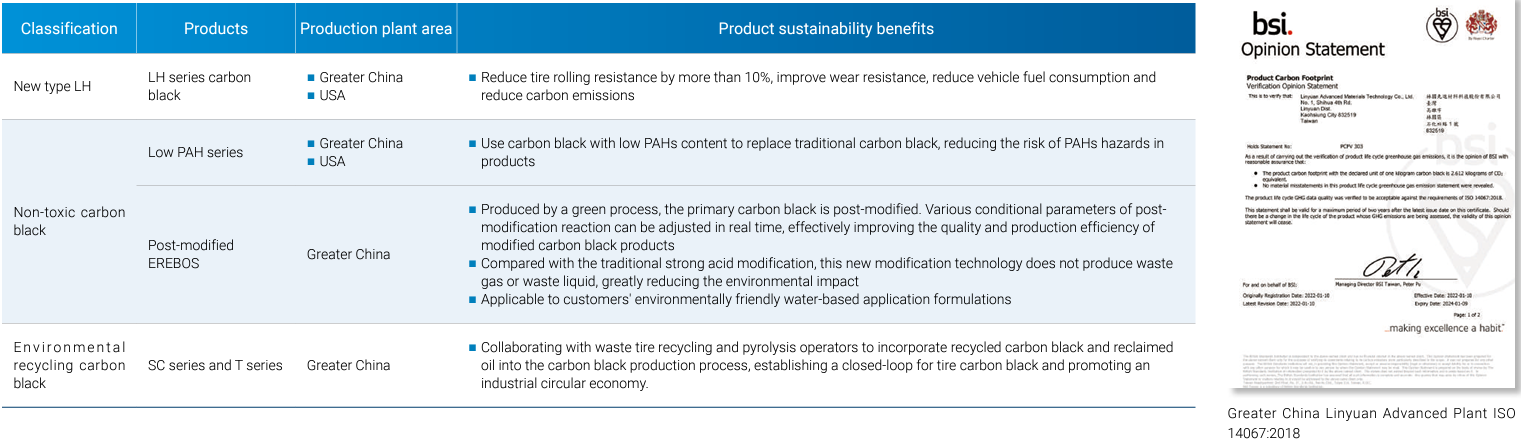

Based on our professional carbon black technology, CSRC is constantly pursuing product innovation. Based on our core concepts and principles, our most important green products are “New LH Series Carbon Black” and “Non-Toxic Carbon Black Series” as well as “Environmentally Friendly Recycled Carbon Black.”

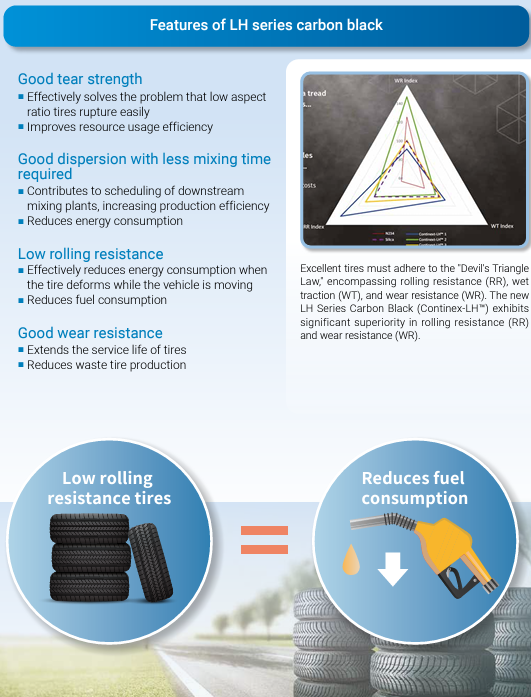

CSRC is actively developing "New LH Series Carbon Black" with high rigidity, low rolling resistance, good thermal aging resistance, and buckling resistance characteristics. These features enhance tire durability and performance for manufacturers and facilitate excellent tire label performance. Through practical testing, tires manufactured using the "New LH Series Carbon Black (Continex-LH ™)" show optimized rolling resistance and improved tread wear resistance, in turn reducing vehicle fuel consumption and carbon emissions. According to EU statistics, comprehensive adoption of energy-efficient tires for vehicles across the EU could annually reduce carbon dioxide emissions by 4 million tons, equivalent to removing 1.3 million passenger cars from EU roads each year. CSRC's R&D Center in the United States has obtained relevant patents, including applications for passenger car tire treads and truck tire treads, and will initiate laboratory-scale trials.

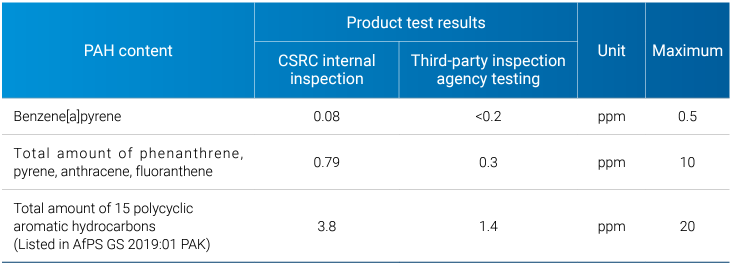

Rubber and plastic (such as ABS and PP) and transparent paints and coatings on natural materials may contain highly hazardous materials such as polycyclic aromatic hydrocarbons (PAHs). In addition, studies have shown that PAHs are most harmful to the human skin and respiratory tract. As persistent organic pollutants, they have been listed as carcinogens by the International Cancer Research Center. In view of this, we are committed to reducing the content of PAHs in carbon black, complying with the second-category requirements of German Safety (GS) standards as issued by Germany's Product Safety Commission (AfPS), and conducting annual tests for PAH limits and content in carbon black, thereby allowing customers to purchase and use our products with peace of mind. In 2023, the Linyuan Advanced Plant in Greater China passed hazardous substance testing for 233 items, achieving a 100% inspection product qualification rate.

Applications of Non-Toxic Carbon Black Series products

Limits and verification of polycyclic aromatic hydrocarbons in carbon black

| Note 1 | CSRC uses the internally developed PAH quick screening method, which can obtain 15 or 18 PAH content, and apply it to screening during the manufacturing process, after packaging, and before shipment. It will also be sent to third-party inspection agencies to obtain reports from time to time. |

| Note 2 | The detection of harmful substances (specific chemical substances) in carbon black production is through photro (toluene transmittance) monitoring, and the detection frequency is once every four hours or eight hours. |

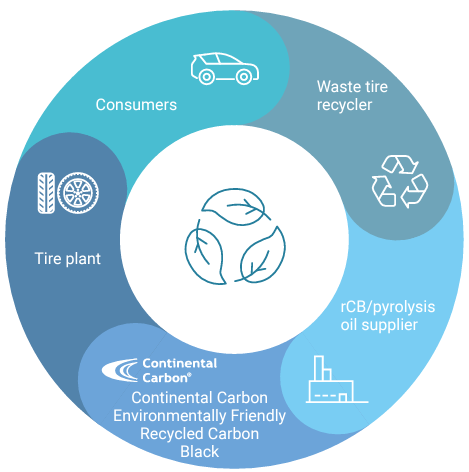

In response to the global net zero emissions trend, we are further introducing the "New Circular Economy Model." Starting from raw materials, we collaborate with waste tire recycling and pyrolysis plant operators to utilize recycled carbon black and pyrolysis oil. Through R&D technology adjustments in carbon black formulation and processes, we produce new "Environmentally Friendly Recycled Carbon Black." This not only meets the tire and rubber industry's demand for sustainable raw materials, but also achieves a closed-loop system for carbon black, thereby achieving the goal of reducing carbon emissions.

The Company continues to invest in R&D to explore various sustainable/renewable materials and energy sources, optimize production processes, improve energy utilization efficiency, and produce stable high-quality "Environmentally Friendly Recycled Carbon Black" suitable for different requirements. Through rigorous quality control, in addition to ensuring tire quality remains unaffected when using low-carbon products, advanced production and blending technologies ensure the physical properties of Environmentally Friendly Recycled Carbon Black match those of virgin carbon black, reducing variability in tire rubber formulations. To meet customer carbon reduction goals, we collaborate with the development needs of downstream tire customers to develop products that meet circular economy requirements and achieve carbon reduction.

In response to international customers' emphasis on product environmental protection and carbon reduction, CSRC actively develops new grades of low-carbon and environmentally friendly carbon black products. The Linyuan Advanced Plant in Greater China obtained carbon black carbon footprint certification in 2022, assisting end customers in meeting green requirements.

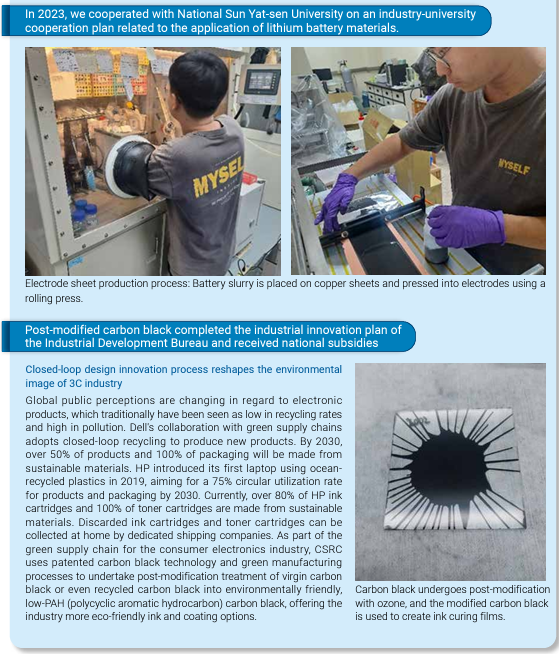

Cases of Industry-Academic Cooperation in 2023

Product R&D Highlights in 2023