We stand by the idea of "Full Participation, Customers First” for our quality policy, establishing a quality management system based on international environmental standards to ensure the good quality of our products. In addition, we also encourage colleagues to actively participate in international seminars every year. Content includes the latest foreign production technology, pollution prevention technology, equipment development, and so on. In this way, colleagues can obtain domestic and foreign market information as well as insights into industry development directions and bring them back to their plants to share with colleagues. Furthermore, technical exchanges among the eight global quality assurance laboratories facilitate the integration of relevant resources and maximization of resource utilization.

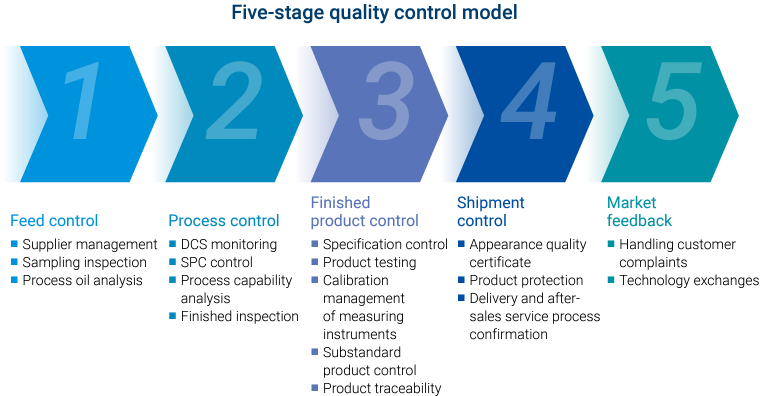

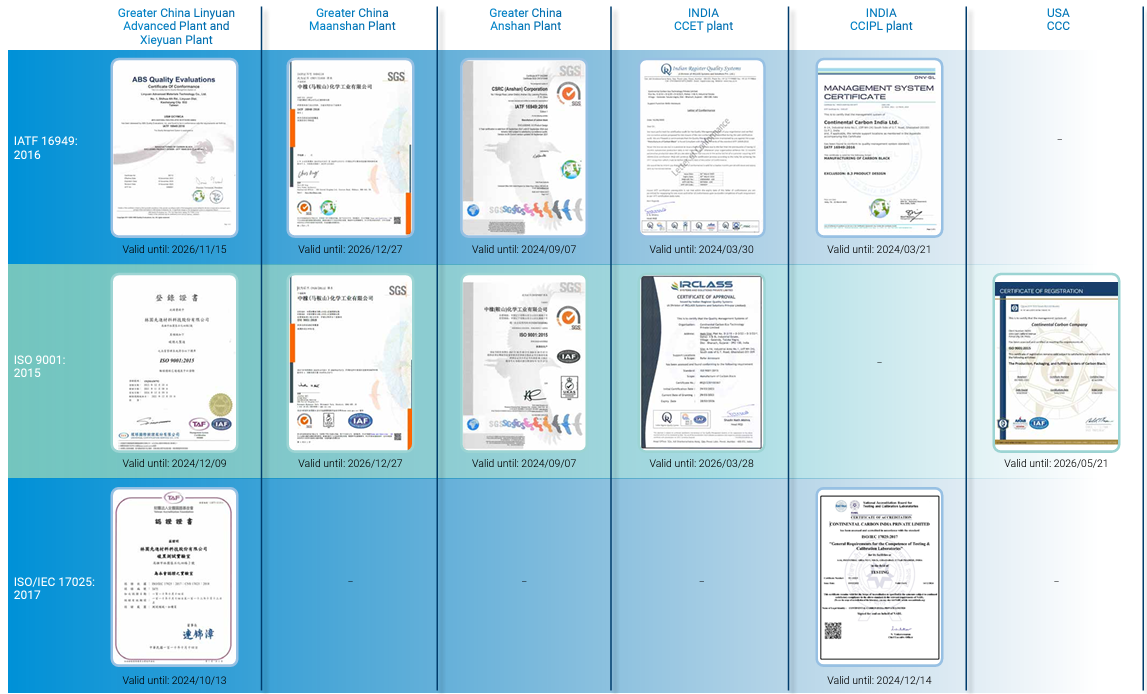

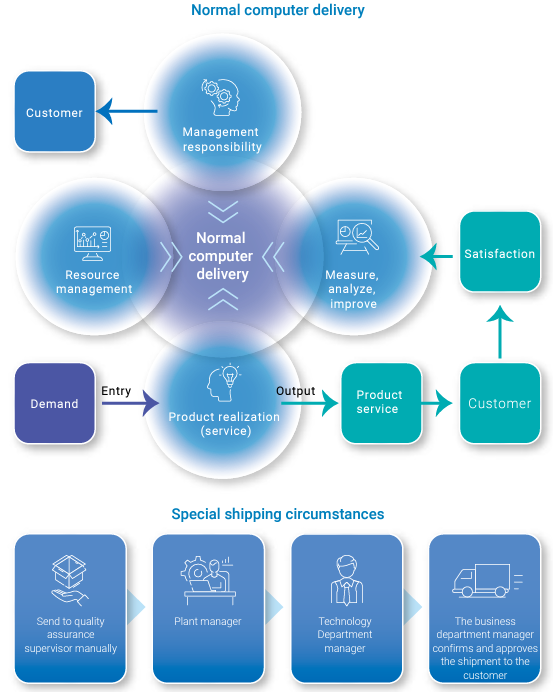

CSRC is committed to meeting customer needs, adopting an organized quality management process, and implementing a "Five-Stage Quality Control Model" that details operational items at each stage. This approach effectively ensures product quality consistency. Through this "Quality Management System," we ensure strict implementation of quality management across departments and conduct checks on compliance with packaging regulations. For products requiring special specifications, we adopt a manual review process, requiring approval from the Quality Assurance Supervisor, Plant Manager, Technical Department Manager, and Sales Department Manager, ensuring delivery to customers only after meeting standards. This series of measures ensures the stability and reliability of product quality, supporting continuous improvement and implementation of the quality management system. To enhance product control and customer trust, some customers visit the plant site annually for second-party audits. Please see 2.4 Customer Relationship Management for details. Each plant obtains relevant external third-party testing for product quality management, such as IATF 16949:2016 automotive quality management system certification and ISO 9001:2015 quality management system certification.

Five-stage quality control model

Quality management related verification certificate

Quality management system process

Special Manual Delivery

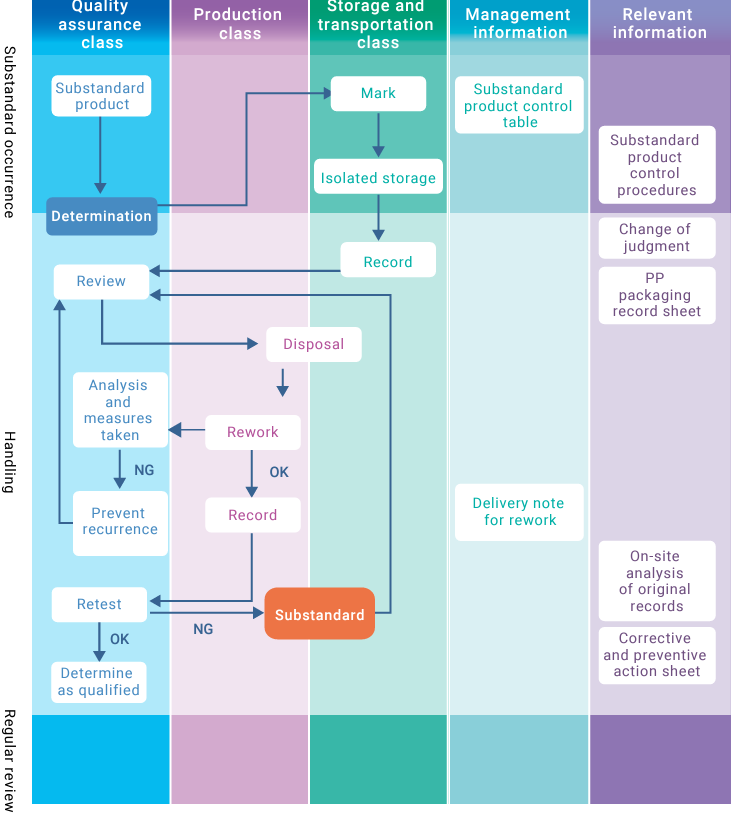

In addition, we also use the PDCA mechanism (Plan, Do, Check, Act) in a continuously dynamic cyclical process to review quality management procedures, adjusting and optimizing at any time to pursue higher product quality. In case of non-conforming products, they will be handled in accordance with the internally formulated nonconforming control procedures.

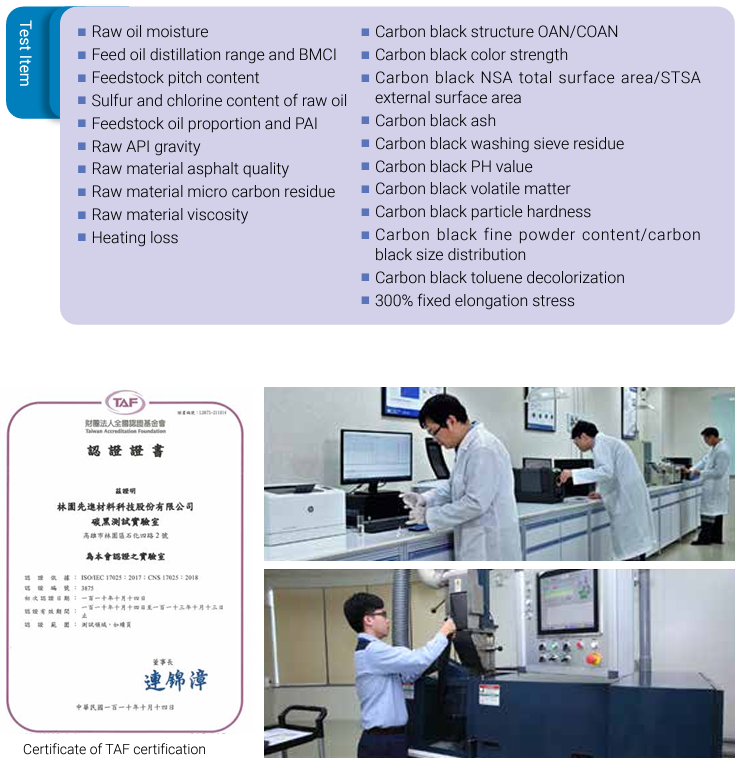

CSRC self-inspects product quality in all aspects to enhance product safety. Among these, the carbon black laboratory of the Linyuan Advanced Plant in Greater China has been accredited by the Taiwan Accreditation Foundation (TAF) and announced as a TAF certified laboratory. Details of self-inspection items for CSRC products are as follows:

- Raw oil moisture

- Feed oil distillation range and BMCI

- Feedstock pitch content

- Sulfur and chlorine content of raw oil

- Feedstock oil API gravity

- Raw material asphalt quality

- Raw material micro carbon residue

- Raw material viscosity

- Heating loss

- Carbon black structure OAN/COAN

- Carbon black color strength

- Carbon black NSA total surface area/STSA external surface area

- Carbon black ash

- Carbon black grit

- Carbon black PH value

- Carbon black volatile

- Carbon black particle hardness

- Carbon black fine powder content/carbon black size distribution

- Carbon black toluene decolorization

- 300% fixed elongation stress

Substandard product control flow chart

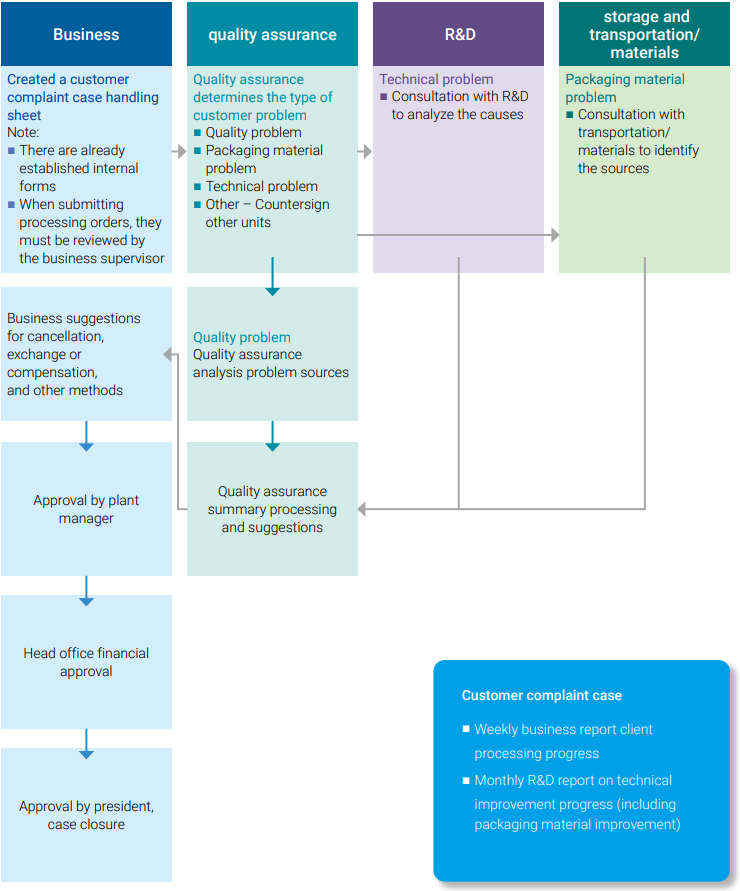

To ensure that all products provided consistently meet customer requirements and standards, CSRC also provides channels for customers to lodge complaints regarding product quality. In case of product-related complaints, they are processed according to the product incident handling procedures.

Product complaint incident handling process

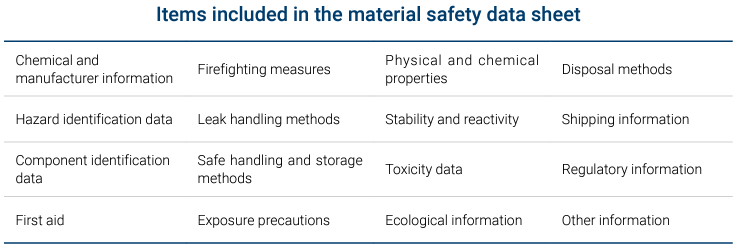

All production processes of CSRC comply with international environmental standards to achieve an optimal balance between corporate development, ESG responsibility, and environmental protection. To enhance the transparency of product information, we regularly update the material safety data sheet (MSDS) and proactively provide product safety features, disposal methods, and other safety information for customers' reference and use. The percentage of products that have undergone regulatory assessment by CSRC is 100%, confirming that all carbon black products are compliant, as they have been fully evaluated and verified.

Items included in the material safety data sheet

| Chemical and manufacturer information | Firefighting measures | Physical and chemical properties | Disposal methods |

| Hazard identification information | Leak handling methods | Stability and reactivity | Shipping information |

| Component identification information | Safe handling and storage methods | Toxicity information | Regulatory information |

| First aid measures | Exposure precautions | Ecological information | Other information |

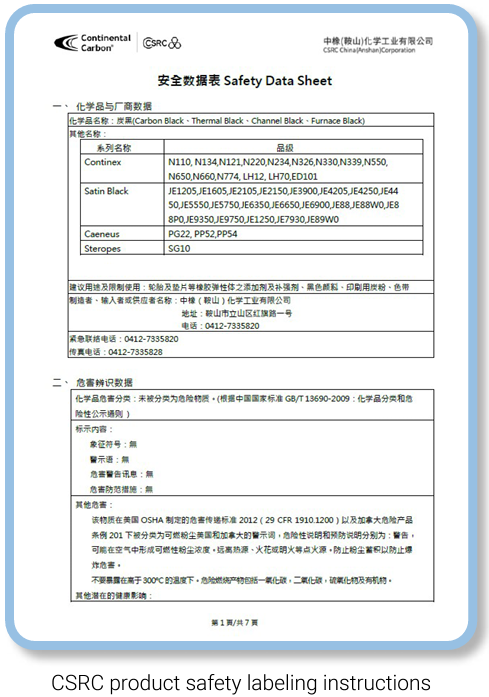

Product safety label examples

At the same time, we cooperate with national transportation regulations, to carefully handle all types of transportation permit qualification certificates before shipping products. We also meet the legal requirements of the country where the product is to be imported, pasting required label contents on the packaging to indicate batch, production date, product name, place of origin, safety, etc. and provide safe and environmentally friendly product information to avoid client and consumer misuse. In 2024, CSRC had no violations related to product safety labeling, and product-related health & safety regulations.