CSRC attaches great importance to the safety and health of all employees in the working environment. Our policy guidelines for occupational health and safety constitute "safety first, prevention first, comprehensive management, people-centric, safety development, full participation, pursuing excellence, and continuous improvement." Our highest guiding principle is accident prevention. The CSRC Safety and Environmental Center is responsible for coordinating the safety and health regulations, formulating strategies, conducting hazard assessments and risk identification, planning safety and health family activities participation, and monitoring and managing the environmental safety performance of its operating units. Occupational Safety and Health Committees are established at each of our global operating locations, with plant managers serving as chairpersons. Committees in Greater China and India meet every three months, while those in the United States convene monthly. The meetings primarily focus on communicating and discussing occupational safety and health policies, management and implementation plans, environmental monitoring plans, safety and health education and training implementation plans, occupational incident investigation reports, on-site safety and health management performance, and other related occupational safety and health management matters.

| Region | Greater China | India | USA | Group |

|---|---|---|---|---|

| Total number of individuals | 57 | 132 | 4 | 193 |

| Labor representation ratio | 49% | 35% | 50% | 39% |

CSRC Safety and Health Policies and Concepts

- Comply with all applicable laws, regulations and other requirements.

- Provide appropriate protective measures, equipment or work control to prevent injuries and occupational diseases.

- Strengthen equipment maintenance and continuous improvement to eliminate or reduce any harm arising from equipment.

- Carry out safety and health education for relevant personnel with employees' awareness of hazards in the workplace; improve independent safety and health management capabilities.

- Establish good communication channels for participation in consultation, enabling stakeholders and employees to understand safety and health management policies and related requirements. Work together to improve inappropriate issues and create a safe and comfortable working environment.

- Provide the necessary resources to maintain the effective operation of the occupational safety and health management system, and continuously improve safety and health management and performance.

- Recommendations on Occupational Safety and Health Policies.

- Coordinate and recommend occupational safety and health management plans.

- Review implementation plans for safety and health education and training.

- Review the operational environmental monitoring plan, monitoring results, and measures to be taken.

- Review health management, occupational illness prevention, and health promotion matters.

- Consider various safety and health proposals.

- Review automatic inspection and safety and health audit matters among business units.

- Review preventive measures for machinery, equipment or raw materials, and hazards from materials.

- Report on occupational hazard inquiry review.

- Assess on-site health and safety management performance.

- Review health and safety management matters among contracting businesses.

- Review of comprehensive emergency response plans for sudden incidents, project responses, and on-site disposal plans.

- Review of annual safety production responsibility system assessments.

- Specialized advocacy on occupational safety and health knowledge. Examples include unsafe actions and conditions, accidents and fire drill simulations, arc flashes, safety boots, hearing protection, gloves, Management of Change (MOC) procedures, cleanliness, and safe electricity use.

- Review occupational safety and health management matters among contractors.

- Annual employee health check-up arrangements and discussions of women's health initiatives.

- Review and declaration of occupational safety goals.

Executive Management Support and Involvement in Occupational Safety and Health

CSRC holds a monthly occupational safety meeting for the Greater China region, attended by plant managers and the environmental health and safety center director, reporting execution status to the Chairman, President, and executive team. Each production site implements related improvements as per meeting resolutions to enhance occupational health and safety management. A total of 12 safety meetings were held in 2024.

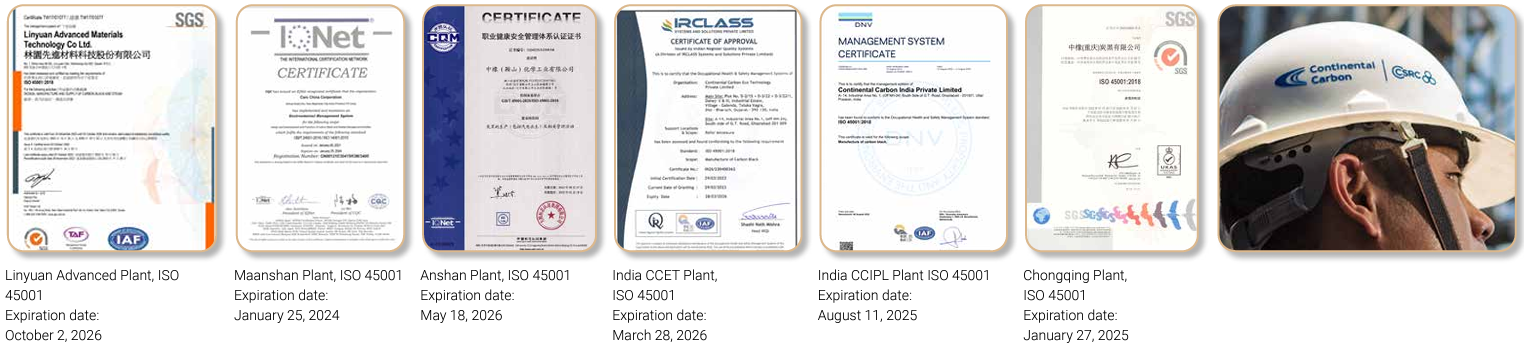

CSRC continues to promote the operation of ISO 45001 and GBT management systems through dedicated safety and environmental units at each plant. The company strengthens emergency response drills to achieve disaster reduction and damage mitigation. During major overhauls, contractor management is implemented to reduce the occurrence of accidents. Health services are provided, and health promotion is actively pursued. By utilizing management systems, the company continuously reduces occupational safety and health risks to achieve set goals.

We comply with the laws and regulations of each region, including Taiwan's Occupational Safety and Health Act, Process Safety Management, and Labor Health Protection Rules. In mainland China, we adhere to regulations such as the New Safe Production Law, the Basic Law on Labor Protection, and the Law on the Prevention and Control of Occupational Diseases. In India, we follow regulations such as the Factories Act 1948. In the United States, we comply with the requirements of the Occupational Safety and Health Administration (OSHA) and integrate occupational safety and health systems. Based on these, we establish occupational safety, health, and environmental policies.

Coverage ratio of CSRC's occupational health and safety system for 2024:

Workers defined by CSRC's occupational health and safety management system include company employees and non-employees (such as contractors). Management scope covers all employee workplaces and commuting routes, where contractors follow employer (or agent employer) instructions and handle labor-related affairs in designated areas.

As of the end of 2024, ISO 45001 certification has been obtained for all six production sites globally, including the Greater China and India regions, achieving 100% coverage in system specifications for employees and non-employeesNote. In the US region, internal occupational health and safety system coverage also reaches 100%.

CSRC prioritizes the safety and health of its employees, dedicating itself long-term to providing a safe working environment and maintaining the physical and mental well-being of employees. We firmly believe that only healthy employees can contribute to the Company's success. To implement safety and health policies, CSRC sets various safety and health management goals every year based on annual objectives and follows the safety and health management system to promote continuous operational improvements. This is aimed at reducing hazardous factors that jeopardize safety and health, preventing accidents, and enhancing the safety and health of employees.

2024 Employee occupational injury statistics

CSRC Group Occupational Injury Statistics for Employees in the Past 3 Years

| 2022 | 2023 | 2024 | |

|---|---|---|---|

| Total working hours | 2,295,319 | 2,504,293 | 2,497,786 |

| Number of general occupational injuries | 10 | 7 | 2 |

| Number of severe occupational injuries | 4 | 1 | 1 |

| Number of deaths | 0 | 0 | 0 |

| Total number of recordable occupational injuries | 14 | 8 | 3 |

| Total Recordable Injury Rate (TRIR) Note1 | 1 | 0.64 | 0.24 |

| Severe occupational injury rate Note2 | 2 | 0.40 | 0.4 |

| Resulting from occupational injuries Death rate Note3 | 0 | 0 | 0 |

| Disabling injury frequency rate (FR) Note4 | 6 | 3.19 | 1.20 |

| Lost days Note5 | 332 | 599 | 640 |

| Severity of disability injury (SR) Note6 | 145 | 239 | 256 |

- Covers 100% of group employees, except for the India CCET Plant which commenced operations at the end of 2022 and is thus included in the statistical scope starting from 2023.

- Total Recordable Injury Rate (TRIR) = (Recordable number of occupational injuries x 200,000 working hours) / Total working hours.

- Severe occupational injury rate (excluding deaths) = [Number of serious occupational injuries (Excluding deaths) x 1,000,000 working hours] / Total working hours.

- Rate of death caused by occupational injuries = (Number of deaths caused by occupational injuries x 1,000,000 working hours) / Total working hours.

- Disabling injury frequency rate (FR) (Also known as "Recordable Occupational Injury Rate") = (Recordable number of occupational injuries x 1,000,000 working hours) / Total working hours.

- Calculated from the date of injury, the total loss of days after all injuries occurring in a single case. The number of days the injured person is temporarily (or permanently) unable to return to work. The day of injury and the day of returning to work are not included, but the number of days elapsed in between (including Sundays, holidays or business unit off-work days) and any days of inability to work due to the disaster after returning to work between.

- Severity of disability injury (SR) = (Number of lost working days x 1,000,000 working hours) / Total working hours.

Non-employee occupational injury statistics

| 2022 | 2023 | 2024 | |

|---|---|---|---|

| Total working hours | 1,152,547 | 1,806,777 | 1,963,781 |

| Number of general occupational injuries | 0 | 0 | 1 |

| Number of severe occupational injuries | 0 | 0 | 0 |

| Number of deaths | 0 | 0 | 1 |

| Total number of recordable occupational injuries | 0 | 0 | 2 |

| Total Recordable Injury Rate (TRIR) Note1 | 0 | 0 | 0.20 |

| Severe occupational injury rate Note2 | 0 | 0 | 0 |

| Resulting from occupational injuries Death rate Note3 | 0 | 0 | 0.51 |

| Disabling injury frequency rate (FR) Note4 | 0 | 0 | 1.02 |

| Lost days Note5 | 0 | 0 | 6,074 |

| Severity of disability injury (SR) Note6 | 0 | 0 | 3,093 |

- Non-employee statistical scope includes temporary workers, security personnel, and contractors.

Group over the past three years for process safety incidents

| 2022 | 2023 | 2024 | |

|---|---|---|---|

| Total Number of Process Safety Incidents (PSIC) | 3 | 2 | 1 |

| Total Incident Rate (PSTIR) | 1.2553 | 0.7948 | 0.4284 |

| Incident Severity Rate (PSSIR) | 1.2553 | 0.7948 | 0.4284 |

- The calculation coefficients for the process safety incident rate and incident severity rate in 2022 and 2023 were incorrectly entered, and have now been uniformly updated.

Prevention of transportation safety incidents

CSRC attaches great importance to transportation safety. During the supplier evaluation process, we include supplier transportation mode as one of the evaluation items. Suppliers that provide transportation services must meet a certain evaluation score in order to maintain a contracting relationship with CSRC. If there will be exposure to chemicals during transportation, relevant personnel must wear personal safety protective equipment throughout the operation in accordance with the regulations. Furthermore, they must understand the operation safety operation standard procedures. In 2024, there were no major transportation accidents where raw materials or chemicals were leaked.