CSRC places great importance on the handling of workplace safety incidents and the implementation of immediate reporting procedures. Through the "Hazard Identification and Environmental Safety and Health Inspection Mechanism," the company actively eliminates potential hazards in the workplace. Routine automatic inspections are reinforced within the plant, and in the event of any accidents or abnormal incidents, the abnormal reporting and emergency response procedures are activated. Employees are required to leave their workstations immediately to report the incident, ensuring that the severity of the incident is minimized as quickly as possible. Subsequently, incidents are managed according to their severity, thoroughly investigated, and review reports are issued. The findings are incorporated into the annual review and improvement of occupational safety systems to achieve the goal of creating a healthy and safe working environment for employees.

In our training courses for new employees, we also explain how to respond to emergencies encountered at work. If there is an immediate danger in the workplace, the employer or the person in charge of the workplace must stop operations and ensure that workers evacuate to a safe location. If workers discover an immediate danger while performing their duties, they are allowed to stop work and evacuate to a safe location without endangering the safety of other workers, and must immediately report to their direct supervisor. We also guarantee that no worker will be dismissed, reassigned, denied wages for the period of work stoppage, or subjected to any other adverse treatment for taking such actions.

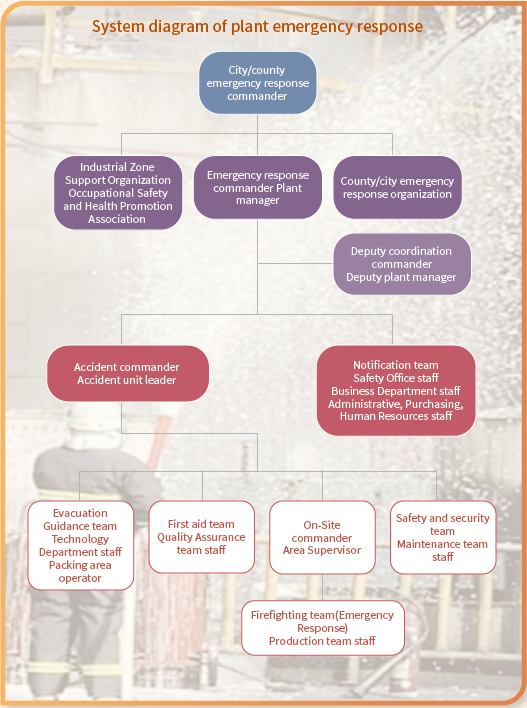

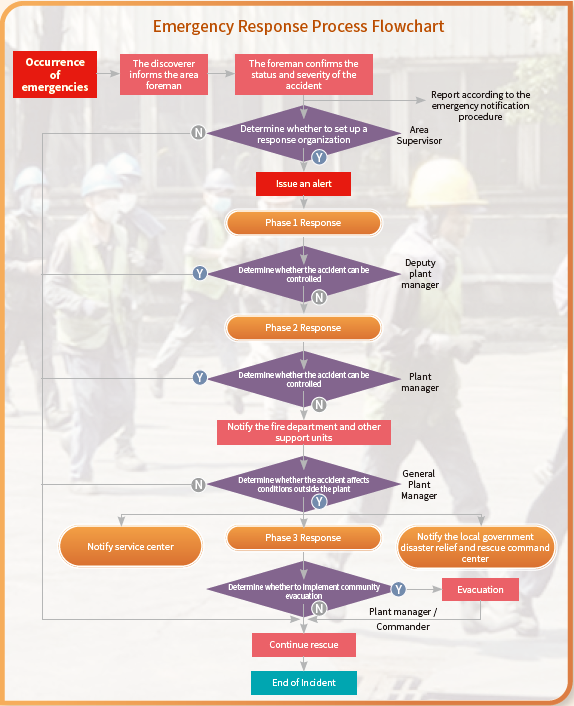

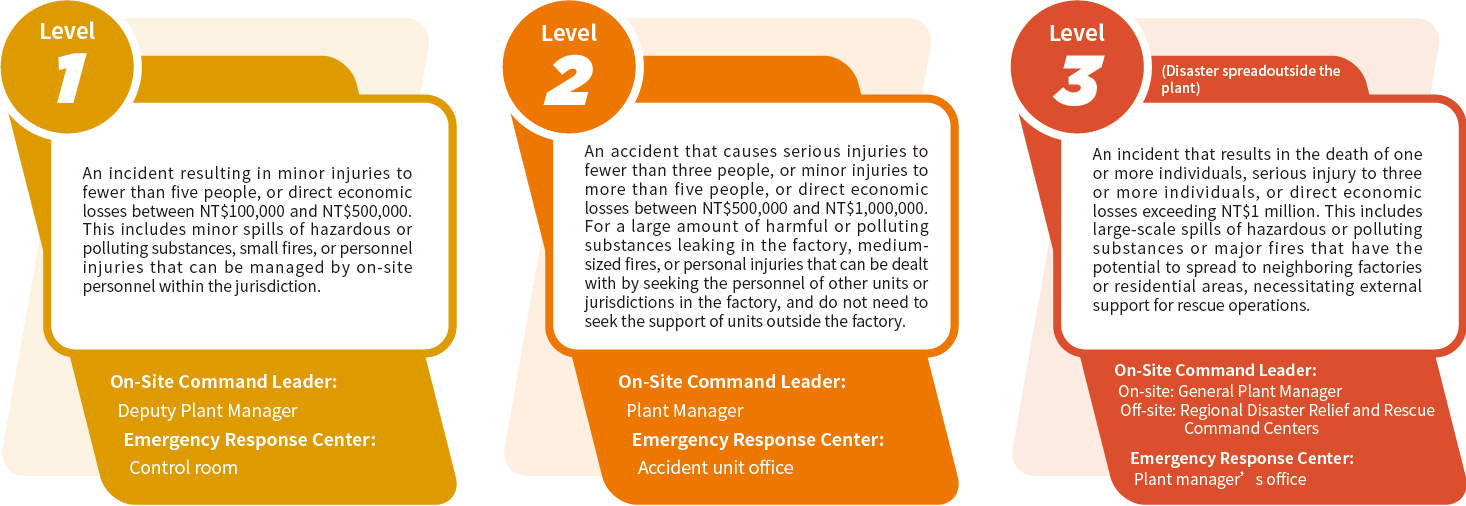

All operational plants have established emergency response plans. For instance, the Linyuan Advanced Plant in the Greater China, when an emergency incident occurs, the area supervisor is first notified. The supervisor then decides whether to form a response team and initiate a Level 1 incident response. If the situation cannot be controlled, it escalates to Level 2, at which point management takes command and notifies the fire brigade and other support units. If the incident escalates to Level 3, indicating an impact beyond the plant, a full emergency response plan is activated for real-time management. This involves collaboration between internal and external units to handle the crisis.

Hierarchical control

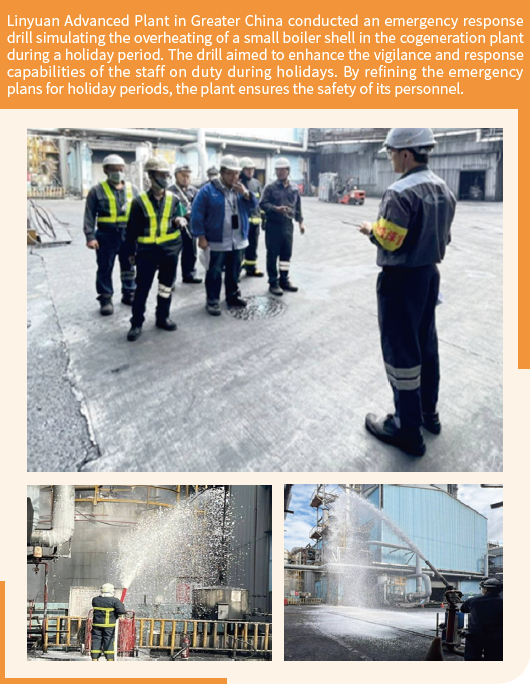

CSRC conducts annual emergency response drill plans in addition to regular fire drills at each of its plants. This is aimed at making personnel familiar with the process flow through continuous training.

Number of emergency response drills conducted by the group and regional sites in the past three years

| Region | Greater China | India | USA | Group | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | |

| Number of emergency drills | 53 | 43 | 35 | 2 | 5 | 2 | 2 | 3 | 6 | 57 | 51 | 43 |

| Frequency of fire drills | 22 | 25 | 12 | 4 | 6 | 7 | 2 | 3 | 6 | 28 | 34 | 25 |

- The number of emergency response drills in the Greater China region in 2024 was lower than in 2023. This was due to major overhaul activities at the Linyuan Advanced Plant from May to August, and the shutdown at the Chongqing Plant in the second half of the year due to acquisition strategies. Nevertheless, the number of drills remained compliant with legal requirements.

Linyuan Advanced Plant in Greater China

Maanshan Plant in the Greater China

Anshan Plant in Greater China

CCIPL Plant in India

CCET Plant in India