Health is invaluable in life. In addition to striving to prevent colleagues from being harmed in the workplace, CSRC also focuses on the overall health of employees. In order to take good care of the health of all colleagues, CSRC continues to introduce relevant safety and health mechanisms through the mechanism of PDCA; and we implement, track, and improve related procedures to provide high-quality employee health and safety services. We also prioritize employee personal privacy and security. We do not track what is discussed with medical staff, safeguarding employee rights.

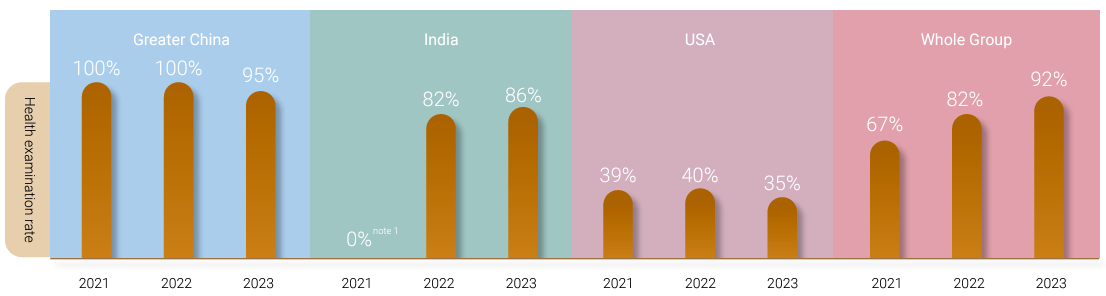

In addition to occupational health services, CSRC also provides all employees with personal health checkups at cooperative hospitals every year. In addition to the personal health check services for employees before and on duty, the Maanshan Plant and Anshan Plant in the Greater China also provide personal health checks upon resignation so as to help workers get the most complete health care. After the inspection report of the Linyuan Advanced Plant is released, the hospital will also provide temporary health consultation services for colleagues whose examination items are abnormal.

In order to enhance employee health protection in the workplace, particularly regarding occupational disease screenings, the Linyuan Advanced Plant has upgraded its onsite health services by appointing a full-time nurse, ensuring continuous health care for workers. In addition, we plan special physical examinations for new employees and conduct the Nordic Musculoskeletal Questionnairenote 2 (NMQ) Note as well as occupation-related special health inspections. The target is colleagues who work in environments that are particularly hazardous to health. (This includes those featuring high temperatures, noise, ionizing radiation, abnormal air pressure, lead, tetraalkyl lead, dust, organic solvents, specific chemical substances, yellow phosphorus, and other operating environments that are particularly hazardous to health.) In addition to plant employees, the Linyuan Advanced Plant conducts disease assessments for contractors to determine their suitability for 30 types of operations before they can enter the plant for training. Cardiovascular disease or abnormal hearing would make one unsuitable for noisy work; high blood pressure or heart disease would mean an individual is assessed as not suitable for high-temperature work, and so on. These and other regulations are in place to ensure the safety of each project and personnel of CSRC.

In the China area, facilities conduct annual special health checks based on occupational characteristics. The Maanshan factory reported inspection rates of 100% for dust, 100% for noise, and 100% for xylene in 2023. This strengthens occupational health management and services for colleagues. Moreover, the Anshan Plant conducts general health checks once a year in accordance with the "Liaoning Provincial Labor Protection Measures for Female Employees," and has added two new items to the female employees' health checks: gynecological examination and cervical cancer screening. Regarding occupational diseases, the Anshan Plant formulates the annual physical examination plan and the frequency of occupational illness inspection items in accordance with the "Occupational Health Surveillance Technical Specifications." Classification of productive dust operations encompass Level I, once every 4 years; Level II and above, once every 2 to 3 years; 8-hour equivalent sound level of workplace noise ≥ 85 dB, once a year; between 80~85 dB, once every two years. In 2023, 126 individuals at the Anshan Plant participated in the occupational disease physical examination, and the occupational disease physical examination rate was 100%. For contractors, the Anshan Plant requires annually contracted contractors to submit worker's medical examination reports every year.

Employees at the India region CCIPL Plant enjoy annual health check services and have established an Integrated Management System (IMS) to ensure environmental hygiene in the workplace. All employees and temporary workers at the India region CCET Plant receive new and annual health check services, and quarterly monitoring of noise and air quality to protect employee health. In the US area, in addition to providing annual preventive health checks and physical exams for employees, occupational injury and illness service facilities are also available. Preliminary medical services are promptly provided if workers are injured on-site.

Note The health examination rate in India in 2021 was 0, having been suspended due to the pandemic

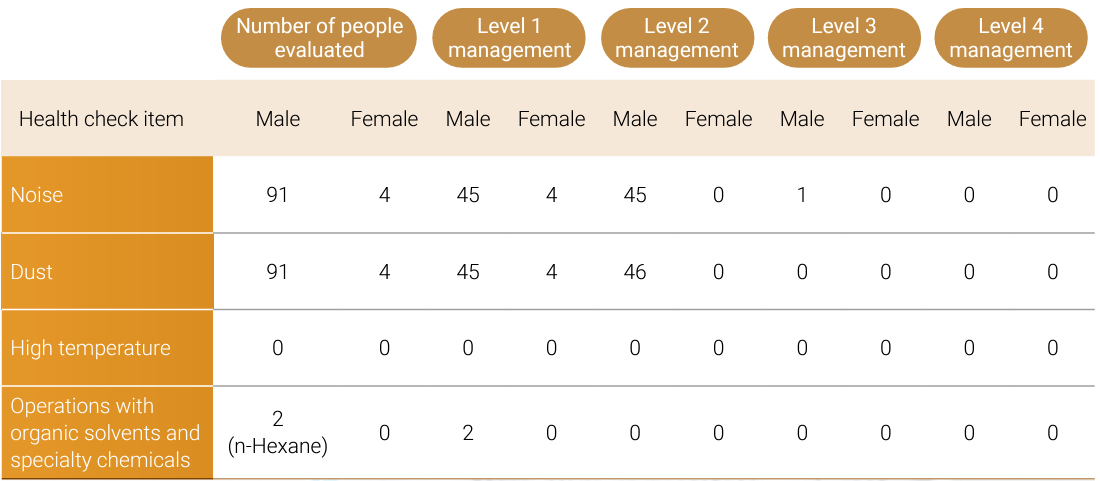

Each CSRC plant identifies potential occupational diseases based on existing hazard identification, distinguishes specialty hazardous operations such as dust and noise, and implements controls and training for these operations. For example, we provide hearing protection education and training, respiratory protection education and training, or reduce exposure time as part of related risk control measures. In terms of personnel, it is not only limited to the control of the job site but also ensures superior to regulatory standards by conducting general and special health checks every year to ensure that employees can work at the plant with peace of mind. In the 2023 statistical dust and noise specialty health inspections, in the health classification, no one exceeded level 2, meaning that either the doctors conducting the special health examinations judged the results as normal, or judged them as abnormal but unrelated to work.

Special hazard occupational health management

The health inspection and health grade management of special hazard operations in Greater China (Linyuan Advanced Plant) are as follows:

Odor Control

Due to the dispersion of powdered carbon black during the production process of carbon black products, granulation is required to reduce transport emissions. The bonding material used during granulation is general edible-grade molasses, but molasses often produces oxidation during drying and the sweetness of the caramel causes odors in the surrounding environment. The Linyuan Advanced Plant has installed two sets of odor facilities to reduce odor emissions.

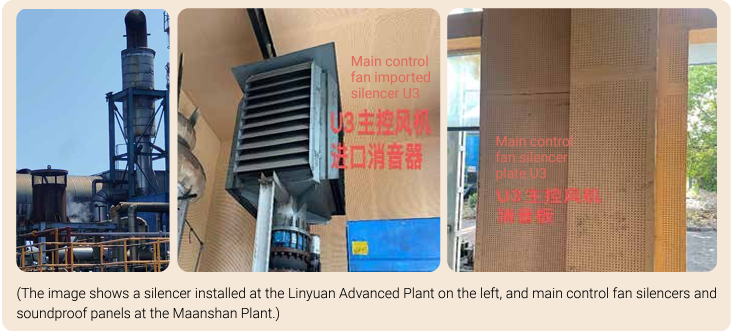

Noise Control

During the start-up and shutdown of steam turbines in the plant, some steam may need to be vented externally, causing noise pollution in the surrounding area. Various types of silencers have been installed throughout the plant to mitigate noise.

The Linyuan Advanced Plant has established a series of prevention plans in recent years, focusing on the prevention of emerging occupational injuries and illnesses. These include prevention of musculoskeletal injuries, prevention of diseases caused by abnormal workloads, prevention of illegal infringements in performing duties, and maternal health protection. The aim is to reduce injuries caused by physical and mental stress among employees. To alleviate employee work stress, a massage therapist is hired every Thursday at the plant to relieve muscle tension. Additionally, lactation rooms have been set up to facilitate female employees in balancing work and family responsibilities.

All plants in the China portion of the Greater China region comply with local occupational disease prevention and control laws, identifying categories of occupational diseases with potential risks, including pneumoconiosis, occupational diseases of the ear, nose, and throat, occupational diseases due to physical factors, occupational skin diseases, and occupational eye diseases. In 2023, no cases of occupational diseases were reported in the China facilities. The Anshan Plant has formulated "Occupational Disease Hazard Risk Grading and Control Measures," and is committed to continuous improvement measures aligning with international standards. In the India region, occupational diseases are identified according to local regulations. In 2023, no occupational disease risks were identified in the two plants. In the United States region, occupational diseases are identified by third-party organizations. There were no cases of occupational diseases reported in 2023.

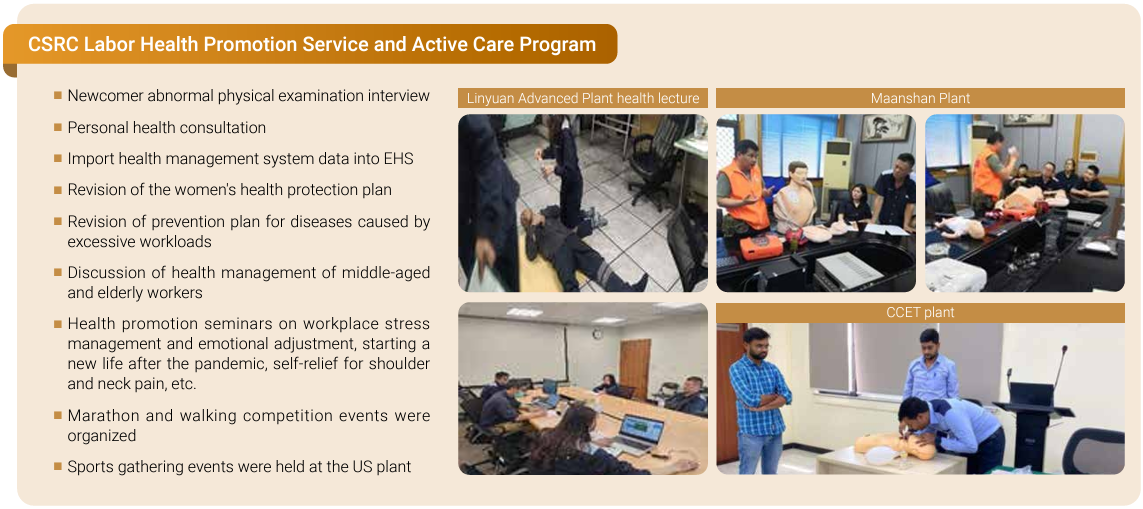

The Linyuan Advanced Plant in the Greater China region has established a labor health service plan to promote voluntary health promotion services for workers: providing health check-ups better than legal requirements, offering appropriate examination packages based on factors such as employee age and health high-risk factors, with family members also participating in health check-up activities. Free influenza vaccinations are available to those eligible for public funding, with appointments made through the health management system. In enhancing the health of female employees at the Maanshan Plant, breast and gynecological ultrasound have been added to health check-up items, and a maternity break room has been set up to practice maternal protection. Health promotion activities were held 231 times across all plant locations in 2023.

CSRC Labor Health Promotion Service and Active Care Program

Workplace maternal health protection measures