CSRC requires new employees to participate in a 6-hour 'New Employee Safety and Health Education Training' course and must pass a test. Existing employees also participate in occupational safety and health-related education and training regularly every year, which focuses on the management of the working environment, equipment, and hazardous substances, enhancing employees' safety awareness and their ability to handle emergencies and self-rescue skills. Various evaluation methods such as written examinations, oral examinations, practice, study reports, and other methods are used to ensure the effectiveness of the education and training. In 2024, a total of 792people participated in CSRC Group's occupational safety and health-related training, accumulating a total of 8,170 training hours.

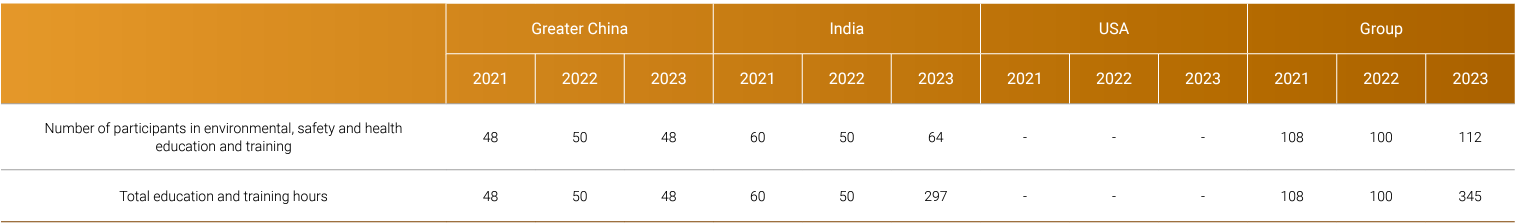

| Region | Greater China | India | USA | Group | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | |

| Number of participants in environmental, safety and health education and training | 737 | 692 | 357 | 228 | 351 | 256 | 201 | 201 | 179 | 1,166 | 1,244 | 792 |

| Total education and training hours | 2,843 | 11,608 | 6,214 | 228 | 1,001 | 1,419 | 3,894 | 3,842 | 537 | 16,325 | 16,451 | 8,170 |

- The course content is related to occupational safety and includes general operation training, hazardous operation training, AED operation training, hazard identification training, emergency response drill weekend classes, respiratory protection training, hazard identification and risk assessment, hazard general education training, chemical protection, and personal protective equipment-related training.

- In 2024, the number of participants and training hours for EHS (Environmental, Health, and Safety) education and emergency response drills in the Greater China Region decreased compared to 2023, due to the major overhaul at the Linyuan Advanced Plant from May to August and the shutdown at the Chongqing Plant in the second half of the year due to acquisition strategies.

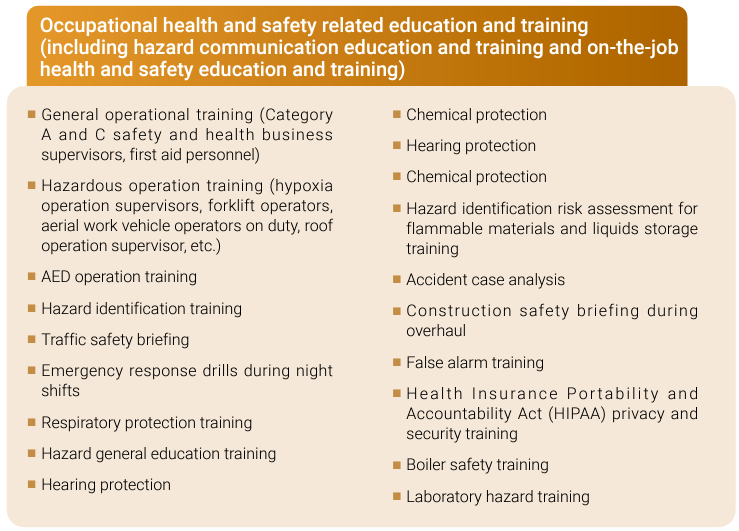

The occupational safety and health education and training categories and course highlights implemented by CSRC are as follows:

(Including hazard communication education and training and on-the-job health and safety education and training)

- General operational training (Category A and C safety and health business supervisors, first aid personnel)

- Hazardous operation training (hypoxia operation supervisors, forklift operators, aerial work vehicle operators, roof operation supervisor, etc.)

- Safety guidelines for major overhaul period construction

- AED operation training

- Hazard identification training

- Traffic safety briefing

- Emergency response drills for Weekend Shifts

- Respiratory protection training

- General hazard awareness education

- Hearing protection

- Chemical protection

- Hazard identification risk assessment for flammable materials and liquids storage training

- Accident case analysis

- False Alarm Incident Training

- Boiler Safety Training

(Including on-the-job health and safety education and training)

- Personal Protective Equipment (PPE) safety awareness

Starting from February 2024, the Linyuan Advanced Plant has been issuing a monthly “EHS Bulletin” along with a reading card and a link to a quiz activity form. Each month, one workplace safety-related topic is selected for promotion and a quiz activity. The bulletin and quiz invitations are distributed via email, workgroup chats, and bulletin boards, encouraging employees to participate. This approach aims to communicate key workplace safety points and, through quiz responses, assess employees’ awareness levels to adjust the direction of occupational health and safety promotion accordingly.

Apart from its own employees, CSRC also emphasizes safety management for contractors, transporters, and other partners. We aim to enhance overall occupational health and safety conditions in the industry. In 2024, a total of 9,170 non-employee participants from CSRC Group attended occupational health and safety education and training, totaling 26,638 hours. Courses included training on hazard-related protective measures, preoperation protective planning for high-risk operations (hot work/ high elevation/confined space/oxygen deficiency/maintenance excavation), and emergency situation reporting and advocacy.

During the 2024 major overhaul period at the Linyuan Advanced Plant, which falls in the summer season with high temperatures and elevated hazard risks, when the outdoor heat hazard reaches the highest level (Level 4), in addition to providing related safety training, shaded rest areas with sun protection and cooling facilities are set up at the work sites to enhance heat mitigation.

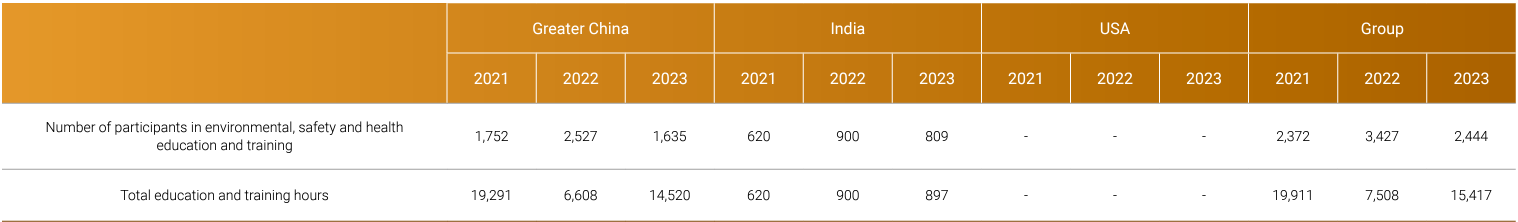

Statistics on safety and health personnel training for contractors by CSRC in the past three years:

| Region | Greater China | India | USA | Group | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | |

| Number of participants in environmental, safety and health education and training | 2,527 | 1,635 | 7,207 | 900 | 809 | 1,861 | - | - | 102 | 3,427 | 2,444 | 9,170 |

| Total education and training hours | 6,608 | 14,520 | 24,786 | 900 | 897 | 1,244 | - | - | 608 | 7,508 | 15,417 | 26,638 |

- No relevant data on contractors was collected in the United States from 2022 to 2023.

- In 2024, the number of participants and training hours for contractor EHS (Environmental, Health, and Safety) education in the Greater China Region increased compared to previous years due to the major overhaul at the Linyuan Advanced Plant from May to August.

CSRC transporter safety and health personnel training statistics in the past three years:

| Region | Greater China | India | USA | Group | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | |

| Number of participants in environmental, safety and health education and training | 50 | 48 | 208 | 50 | 64 | 85 | - | - | 4 | 100 | 112 | 297 |

| Total education and training hours | 50 | 48 | 91 | 50 | 297 | 46.6 | - | - | 32 | 100 | 345 | 170 |

- Statistics for transporters in the United States were not included for 2022-2023.

- Contractors receiving this training should adhere to the safety (access control) regulations informed by the course instructors of the plant(s).

- Contractors must strictly adhere to hazard-related protective measures that may arise from machinery, equipment, and raw materials upon entering the plant.

- Contractors must obtain an identification card issued by the factory to be qualified to enter the factory.

- Before entering the workplace at the plant(s), contractors must notify or obtain approval from the supervisor in charge of the respective jurisdiction of the workplace.

- Pre-operation protection plan for high risk (fire/elevated (location)/hypoxia/annual repair/excavation).

- Notification and evacuation procedures in the event of various incidents within the plant (site), such as occupational accidents, fires, explosions, and other emergencies.

- Before leaving the factory (site) every day, the construction site should be cleaned up and the safety checkpoints (water / electricity) and other work alert zones should be separated, and it should be confirmed that the personnel have left the factory safely.

- If there are safety and health risks on site, contractors must stop work and make improvements immediately.

- Workers who are diagnosed by a doctor or feel unwell should make inquiries.

- Contractor entry management procedures, health and environmental protection requirements, construction site safety awareness, construction site emergency response, and fire handling training.

- Defensive driving and road safety

- Emergency Response Team (ERT) training

- Fire handling training

- Chemical system typical accident cases