CSRC's suppliers are mainly divided into three types: upstream suppliers, downstream suppliers, and other suppliers. Upstream suppliers include raw materials, equipment spare parts, and packaging materials. Downstream suppliers include raw material transportation, finished product transportation, and waste transportation. Other suppliers include contractors for construction and turnkey projects.

CSRC adheres to the philosophy that "ESG is a corporate responsibility, not a cost to the enterprise." To ensure that all risks faced by workers and employees (including contract workers) in the supply chain are adequately understood and managed, CSRC has achieved a 100% signing rate of the " Supplier Corporate Social Responsibility Code of Conduct " and the "Integrity Clause" among suppliers in the Greater China region as of 2024. Moving forward, we aim to extend this requirement to all group suppliers globally, targeting 100% compliance by 2030.EcoVadis is a globally recognized provider of corporate sustainability ratings, offering authoritative assessments through a comprehensive review of key areas such as environmental protection, labor and human rights, business ethics, and sustainable procurement. In 2024, CSRC participated in the EcoVadis assessment for the first time and was awarded a Silver Medal, ranking in the top 15% of all evaluated companies. This outstanding achievement demonstrates our strong performance in sustainability and corporate social responsibility (CSR). Building on this foundation, we will continue to enhance our group-wide performance in the EcoVadis international sustainability supply chain assessment. Our goal is to create lasting value and trust for our upstream and downstream suppliers, the environment, and our own operations.

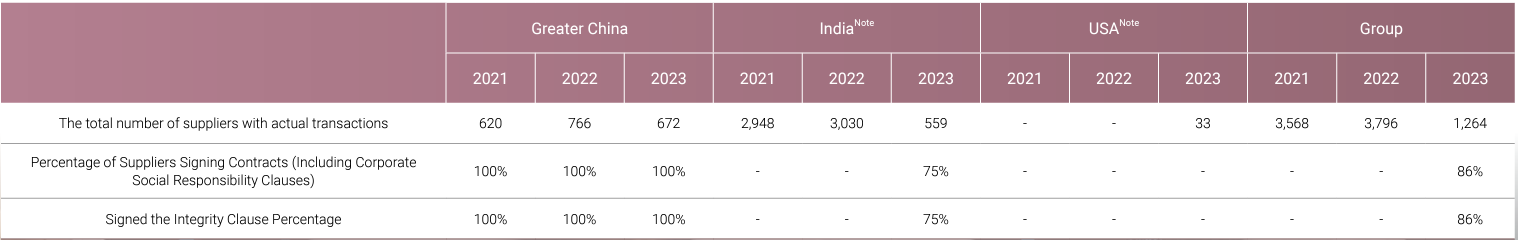

Number of suppliers in CSRC Group and operational plant areas

| Greater China | India Note | USA Note | GROUP | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | |

| The total number of contracted suppliers with actual transactions | 766 | 672 | 645 | 3,030 | 559 | 112 | - | 33 | 34 | 3,796 | 1,264 | 791 |

| Percentage of Suppliers Signing Contracts (Including Corporate Social Responsibility Clauses) |

100% | 100% | 100% | - | 75% | 31% | - | - | - | 86% | 86% | 86% |

| Percentage of Suppliers Signing Integrity Clause | 100% | 100% | 100% | - | 75% | 31% | - | - | - | 86% | 86% | 86% |

- Data for the India region was not compiled by the end of 2022; for the United States region, only the total number of suppliers with actual transaction contracts in the past two years is available, with no other statistical data.

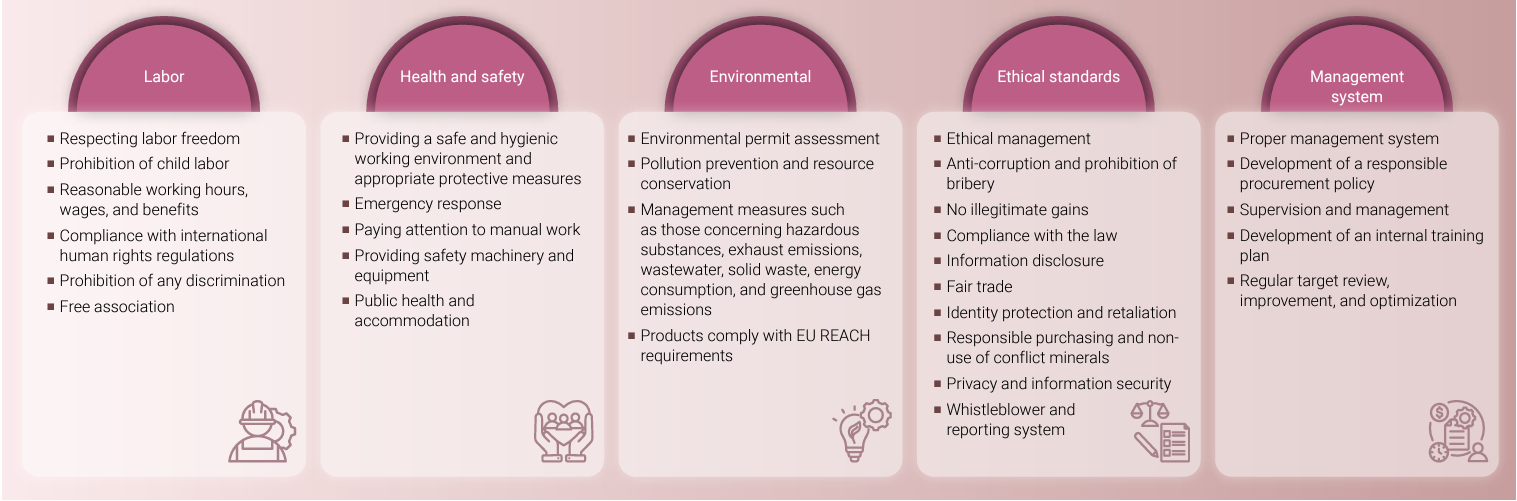

CSRC’s Supplier Corporate Social Responsibility Code of Conduct

- Continuously pay attention to environmental protection, energy saving and carbon reduction, prioritize local procurement, improve energy resource use efficiency, comply with environmental protection laws and regulations, and create a sustainable environment together.

- Comply with relevant waste, waste gas and wastewater management standards. Regarding disposal and treatment of any waste, pollutants and other environmental hazards, all should comply with statutory or international convention requirements.

- Do not employ child labor and protect basic human rights when hiring employees (including but not limited to labor rights, freedom of association, International Labour Organization conventions, etc.). Give reasonable remuneration and provide legal working conditions.

- Uphold business ethics and comply with anti-money laundering and anti-monopoly as well as nondisruptive business competition when running a business.

- Should develop a sustainable procurement policy for its suppliers, and the content of the policy should at least cover the supplier policy issued by the Group.

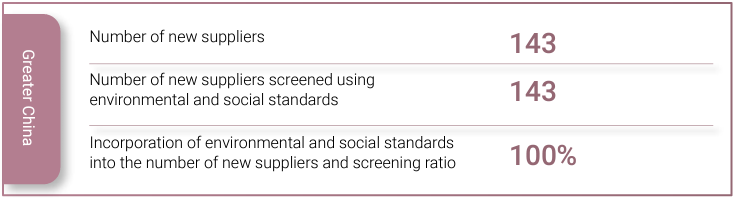

CSRC selects high-quality suppliers through a supplier selection mechanism. Before selection, a supplier will first be required to complete a self-assessment report that includes items such as a company profile, Ministry of Economic Affairs company business registration information, environmental photos of the company's factory, equipment list, R&D technology quality assurance environment, proof of performance (purchase orders, input invoices), and entity finances (balance sheet, income statement). Afterwards, we conduct on-site investigations and visits to the vendors selected based on the self-assessment reports. We assess financial soundness and incorporate social and environmental performance into the criteria for selecting new suppliers. If there are any bad records or major violations related to social or environmental issues (e.g., violations of environmental and social regulations, corporate governance issues such as corruption), we will not cooperate with the supplier. This ensures the effectiveness of our sustainable supplier management. Only suppliers who pass the audit can be listed as qualified suppliers. In 2024, a total of 102 new suppliers were onboarded in the Greater China region, all of whom met our social and environmental screening criteria. In the India region, 108 new suppliers were added, and the implementation of social and environmental screening standards is currently underway, with 10% of new suppliers having already participated in and passed the evaluation. In the United States region, the implementation of social and environmental screening standards is planned for the near future.

Diversity Policy

CSRC is committed to creating an environment that actively embraces Diversity, Equity, and Inclusion (DEI). In the U.S. region, the Group has already advocated for supplier diversity through the establishment of diversity policies, aiming to promote economic growth in all communities, cultivate a more innovative supplier base, and reflect the diverse markets we serve. DEI is prioritized and integrated into our procurement practices, with a focus on enterprises owned by women, minorities, and disadvantaged groups. In 2024, 5.88% of suppliers in the United States region were led by female representatives. In the Greater China region, specifically at the Maanshan plant, 9.1% of suppliers had female representatives in leadership positions.

Number of new suppliers and screening ratio for 2024

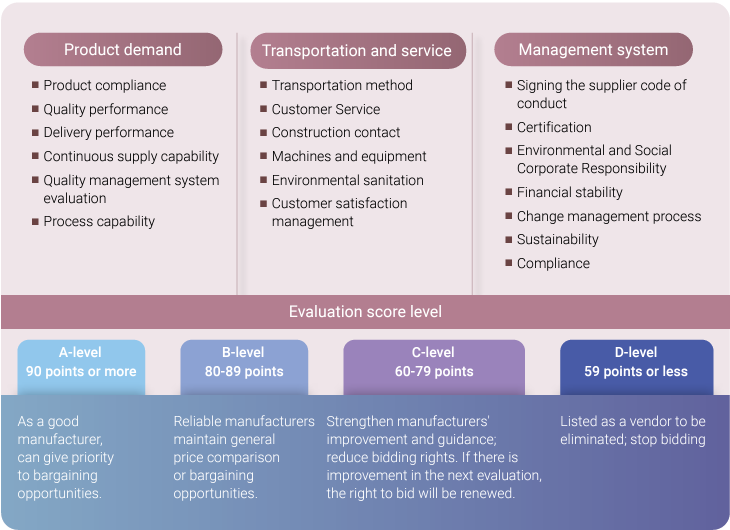

CSRC implements a graded audit once a year for suppliers with transactions to establish sustainable supply chain management. Suppliers are classified into four levels (A, B, C, and D) based on the evaluation score. If a supplier is rated as C-level for two consecutive years, we will conduct a field visit or ask the supplier to visit our facilities for interviews to create written records and assist in improving non-conforming items. Suppliers rated as D-level will be identified for elimination and lose bidding rights.

Starting from 2021, CSRC has conducted on-site audits of the top ten suppliers with the largest purchase amounts on a quarterly basis. The audit includes whether they have signed our supplier code of conduct, obtained relevant certification systems, and practiced environmental or social corporate responsibility. Additionally, from the second half of 2021, the performance appraisal of purchasers has included whether new suppliers have signed ESG clauses. If they do not complete this requirement, the related research report cannot be finalized, and the corresponding performance score cannot be obtained. In 2024, the re-signing rate for ESG clauses among new suppliers in Greater China reached 100%.

To ensure that our supply chain aligns with CSRC’s standards for business ethics and corporate social responsibility (CSR), all material suppliers are required to undergo a CSR risk assessment. In addition, key suppliers must also undergo a business ethics due diligence process. The CSR risk assessment evaluates suppliers’ compliance with our Supplier Code of Conduct, including obligations such as environmental protection declarations, CSR declarations, REACH registration responsibilities, as well as labor practices, occupational health and safety, and ethical management systems. The assessment covers the following aspects: acquisition of relevant certifications, active engagement in environmental or social responsibility initiatives, the presence of systematic and traceable management data, and verification of any violations of legal or regulatory requirements. Furthermore, the business ethics due diligence process for key suppliers incorporates additional ESG (Environmental, Social, and Governance) criteria to ensure comprehensive alignment with CSRC’s standards.

CSRC places great importance on suppliers having their own ESG strategies. The following highlights two key suppliers as examples: CPC Corporation, Taiwan has responded to global economic shifts and the national goal of achieving net-zero carbon emissions by 2050. In alignment with government energy policies and the “5+2 Industrial Innovation Plan,” CPC continues to focus on core technology development with a transformation strategy driven by R&D. The company is advancing transformation along three main pillars: fuel quality enhancement, carbon reduction, and clean energy. Guided by these pillars, CPC actively tracks low-carbon trends and strengthens its product and technology development capabilities through technological integration and strategic alliances. In 2023, CPC allocated NT$3.595 billion to forward-looking R&D initiatives, generating an estimated financial benefit of NT$5.165 billion. These initiatives cover areas such as smart green energy, high-value materials, circular economy, and biofuels, positioning CPC as a key player in the transition to high-value petrochemicals and the green energy industry. China Steel Chemical Corporation aimed to reduce by 2% (1,724 tons) compared to the baseline year in 2023. Through the implementation of 38 energy-saving projects, the company achieved a carbon reduction of 1,870 metric tons—surpassing its target with a 108.5% achievement rate. The company also recorded an average energy savings rate of 1.52%, reflecting strong energy efficiency results. Additionally, China Steel Chemical Corporation completed carbon footprint assessments and verifications for six coal chemical products and four carbon material products, enhancing transparency in carbon management and demonstrating its sustainability performance.

Audit evaluation items and score level

In 2024, the proportion of A- and B-grade suppliers in the Greater China region reached as high as 97.6%, reflecting the effectiveness of our supplier management system, which will continue to be rigorously enforced to encourage ongoing improvement among suppliers. The proportion of C- and D-grade suppliers stood at 2.4%. In the India region, A- and B-grade suppliers accounted for 78%, while C- and D-grade suppliers made up 22%. CSRC requires C-grade suppliers to submit improvement plans and undergo on-site audits with the relevant departments. Cooperation with D-grade suppliers has already been discontinued. CSRC plans to gradually implement supplier evaluations at sites that have not yet adopted the system and will develop improvement plans based on the evaluation results.

| Level | Greater China supplier evaluation | |||

|---|---|---|---|---|

| 2022 | 2023 | 2024 | ||

| A-Level | Number | 505 | 442 | 155 |

| Proportion | 68% | 84% | 62.8% | |

| B-level | Number | 226 | 68 | 86 |

| Proportion | 30% | 13% | 34.8% | |

| C-level | Number | 10 | 13 | 5 |

| Proportion | 1.3% | 2.5% | 2% | |

| D-level | Number | 4 | 3 | 1 |

| Proportion | 0.5% | 0.6% | 0.4% | |

| Total number of evaluations | 745 | 526 | 247 | |

- The Greater China region includes only the Ma’anshan plant in China and the Linyuan plant in Kaohsiung. In 2024, the Chongqing and Anshan plants in China were temporarily shut down due to merger and acquisition strategies during the first half of the year; therefore, no supplier evaluation and grading information is available for these two plants.

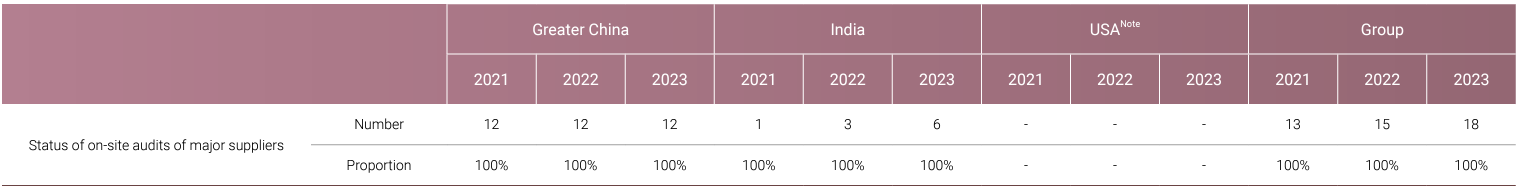

On-site audits of major suppliers

CSRC is committed to sustainable supply chain management. We ensure compliance with ESG standards through rigorous on-site audits of major suppliers. The audit covers environmental management, social responsibility and corporate governance, with the goal of improving the sustainability performance of suppliers, reducing the risk of ESG violations in the supply chain, and promoting transparency in cooperation. The audit process includes planning and preparation, on-site inspections, data analysis, audit reports, and follow-up on improvements. This process enhances supply chain transparency and stability, strengthens market competitiveness, and meets customer and investor expectations for CSRC's sustainable development.

| Greater China | India | USANote | Group | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 | ||

| Status of on-site audits of major suppliers | Number | 12 | 12 | 12 | 3 | 6 | 4 | - | - | - | 15 | 18 | 16 |

| Proportion | 100% | 100% | 100% | 100% | 100% | 100% | - | - | - | 100% | 100% | 100% | |

The 2024 Circular Economy Forum with partners including SHEICO Group.

Green product transportation: Carbon black transportation service providers introduce electric vehicle fleets, reducing transportation carbon emissions

Occupational Safety and Health Management Measures for Contractors

To ensure the safety of contractors or suppliers' work, all project contracts have clearly defined occupational safety regulations. They adhere to the labor safety and health regulations of the country where the plant is located, while also minimizing personnel injuries and fatalities during construction or operations. During the construction process, factory auditors will randomly check the contents of the operation from time to time. If a violation of industrial safety regulations is found, the contractor can be directly requested to stop work. The construction task can be continued after the relevant situation improves.

Environmental Management Measures for Contractors

CSRC and contractors have reached agreement on issues related to environmental pollution. We require contractors to comply with our environmental policy, enhancing environmental cleaning and mobile washing of vehicle tires during engineering or work construction, adhering to environmental protection regulations to avoid any environmental pollution behavior. CSRC will also dispatch supervisors to inspect whether contractors are indeed complying with the regulations. In addition, when the contractor generates general industrial waste, hazardous industrial waste, and resource waste during construction, the supervisor of the project or work organizing department must be contacted to fill out the relevant storage and removal forms. Afterward, the contractor must go to the storage management department that manages various types of waste to handle storage or removal operations; it cannot be thrown away at will.

Contractor education and training

We regularly hold contractor education and training to ensure that the contractor can understand the construction specifications and safety protections. Training content includes the contractor’s entry process description, limited space operation specifications, hot work specification, hanging work specification, information on waste disposal, on-site code violations, information on workplace accidents, etc. For subcontractor education and training, please refer to Chapter 7 on Occupational Safety and Health.