循環創新

循環經濟

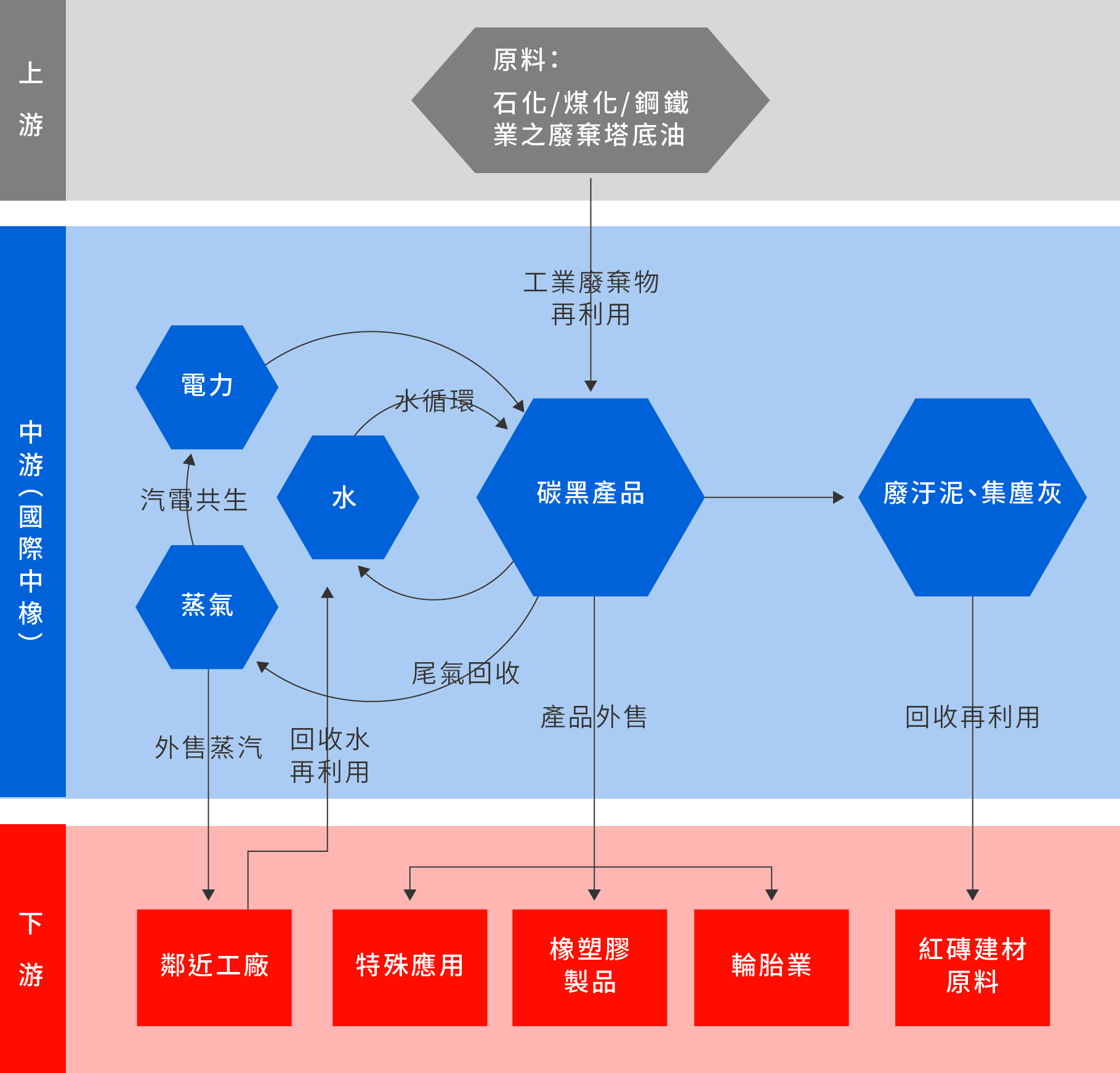

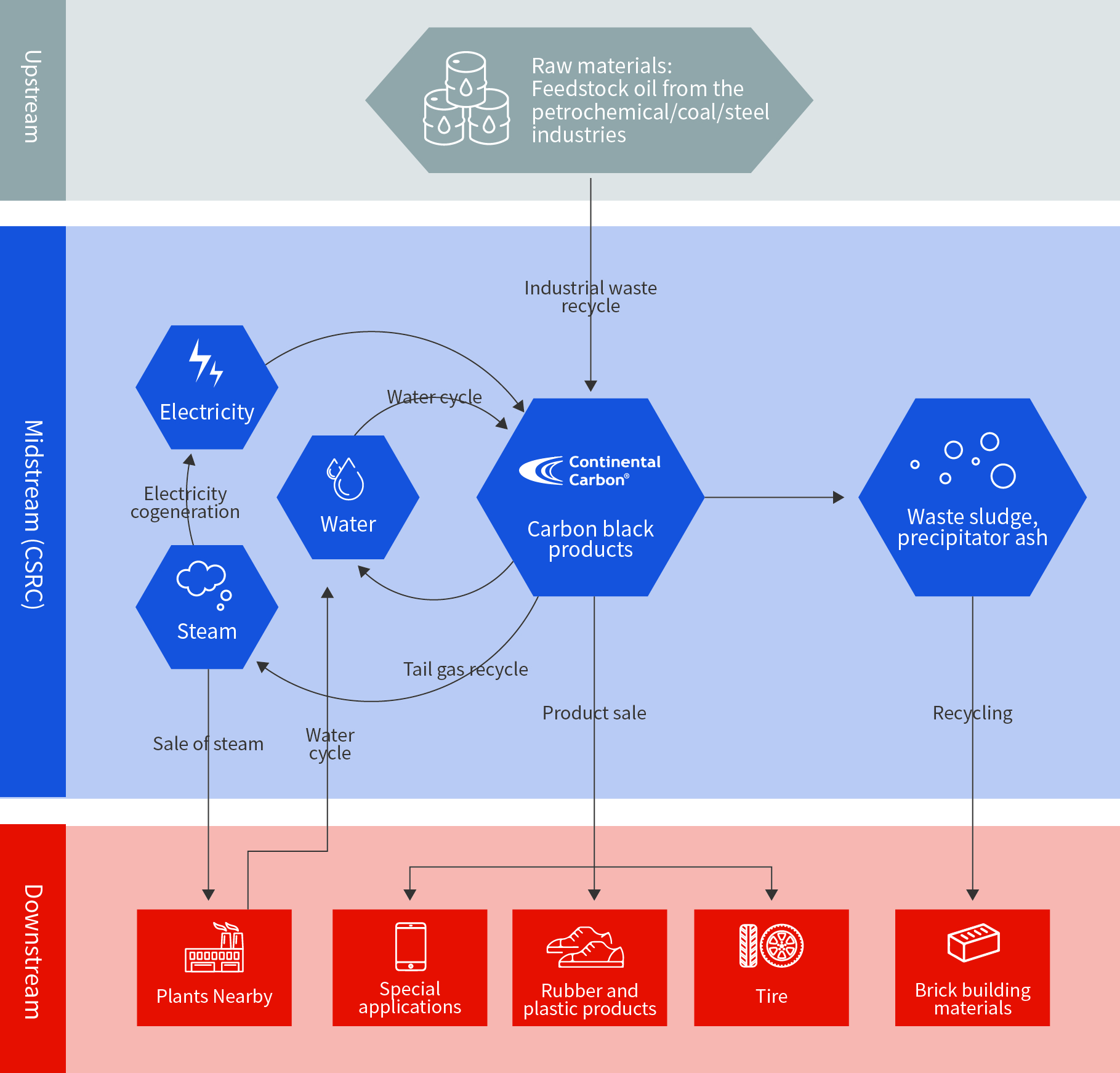

碳黑之價值鏈即是循環經濟模型的典範,其原料來源為上游石化、煉鋼產業在生產煉油過程之殘餘物 (塔底油),這些利用價值低的廢棄物在經過我們的特殊製程後,反而能產生出高價值產品碳黑,以及附加產品蒸汽及電力等潔淨綠色能源,不但減少廢棄物量、降低環境污染風險,更帶動新的產業及科技,創造資源循環利用的經濟典範。

另外,一般焚化爐的溫度只能到達 600-800 度 C,焚燒工業廢棄物後仍會有空汙排放。相較之下,碳黑製程的反應器爐膛溫度高達 1,800 度 C,塔底油在高溫燃燒下可完全去除戴奧辛等許多破壞環境的有毒物質。

CSRC's Carbon Black Business Group actively embraces the operation mode of circular economy to overcome resource depletion issues in traditional linear economies. This includes the continuous reuse of energy resources, extending resource lifespan, and reintegrating end-of-life materials back into production, maximizing resource reuse.

The value chain of carbon black is a model of a circular economy

Its raw material sources include by-products such as bottom oil from upstream petrochemical and steelmaking industries during the oil refining process. These low-value by-products, after undergoing chemical treatment for reuse, can instead produce high-value products like carbon black, as well as additional products such as steam and electricity. The temperature of an incinerator can generally only reach 600-800° C. After incineration of industrial waste, air pollution will still be discharged. In comparison, the reactor furnace temperature of the carbon black process reaches up to 1,800°C. When CSRC incinerates by-products from the petrochemical and steel industries (bottom oil) at high temperatures, it can completely remove many toxic substances such as dioxins that harm the environment. The above carbon black recycling process not only fully utilizes by-products from traditional processes, reducing environmental pollution risks, but also drives new industries and technologies, creating a paradigm of resource recycling.

Practicing the new circular economy model

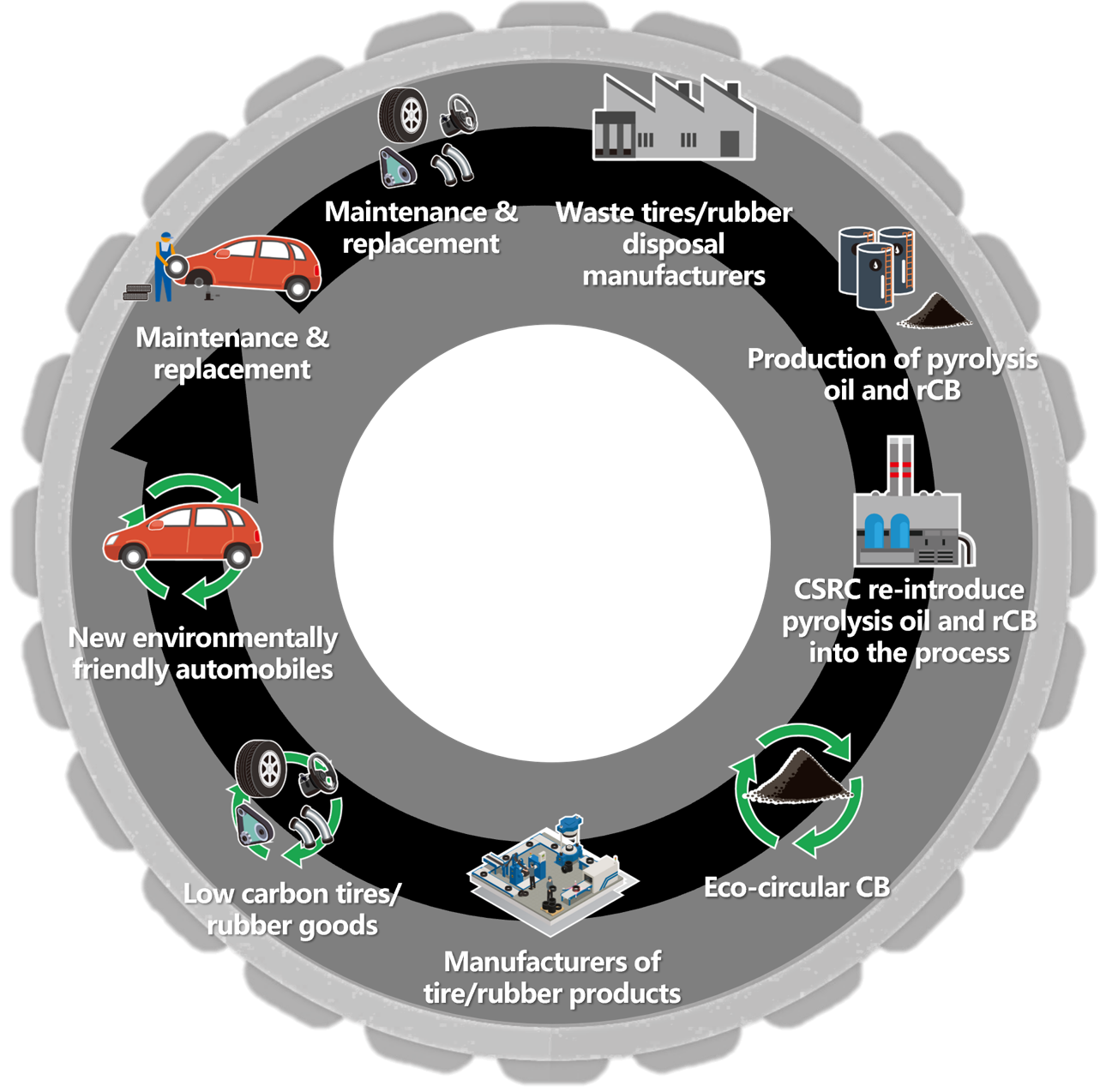

Multinational automotive and related parts manufacturers have made the use of sustainability and recycled materials a core strategy for their development. Carbon black, as an indispensable raw material in tire production, is inevitably part of the entire circular value chain and a key strategy to achieve net-zero emissions in the supply chain.

CSRC aspires to be a pioneer in circular economy and net-zero emissions. The company integrates circular economy principles into its operations and has introduced a "New Circular Economy Model." This model begins with raw materials and involves collaboration with waste tire recycling and pyrolysis companies. These partners produce recovered carbon black and reclaimed oil, which are then reintroduced into the production process. Utilizing CSRC's unique technology, the carbon black formula is adjusted to create new environmentally friendly, carbon-reducing carbon black. This approach achieves a closed-loop system for raw materials and meets the sustainability requirements of tire manufacturers.

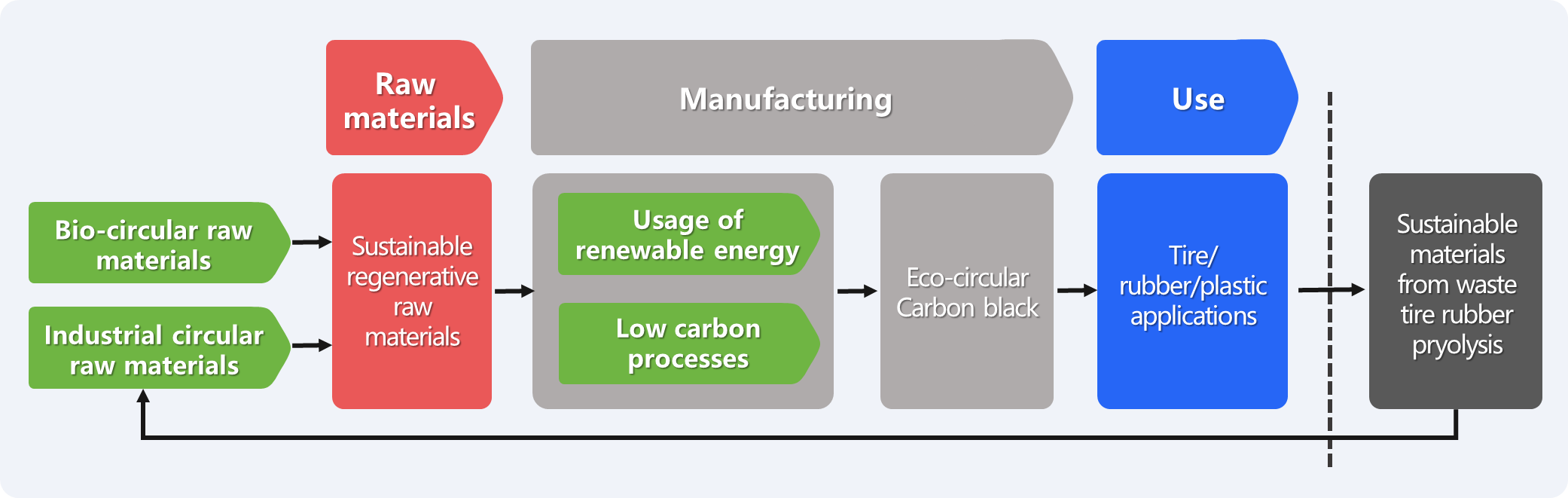

CSRC Upgrads Continental Carbon’s path of the circular economy: Ouroboros-sustainable and regenerative circular solutions

CSRC continuously refines its approach to the circular economy, optimizing and upgrading the existing circular economy path. This involves enhancing the sustainability and renewable raw materials of industrial and biological cycles, as well as advancing technology research and development and process optimization to promote carbon reduction in the regeneration cycle. By employing a multi-faceted approach to upgrade the practical pathways of the circular economy, CSRC aims to achieve the goal of reducing carbon emissions.

綠色產品

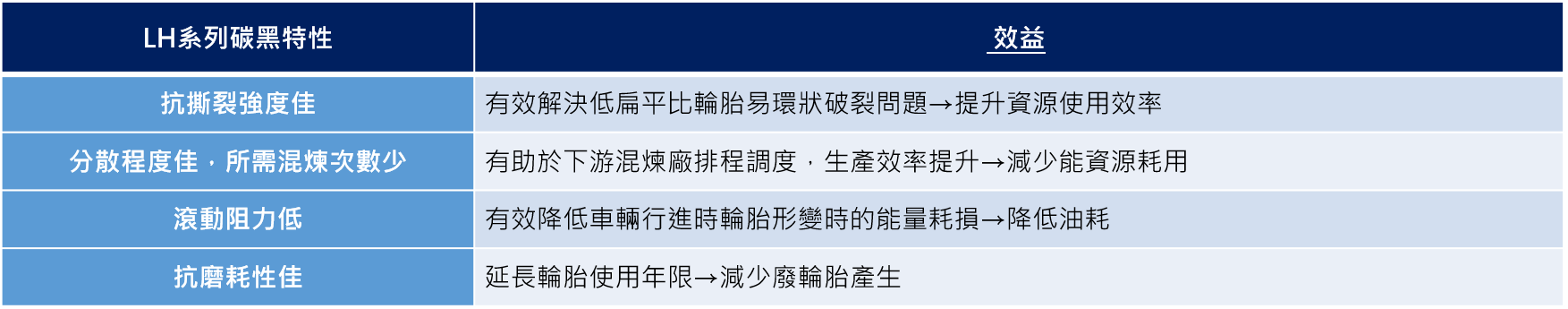

國際中橡以碳黑專業核心技術,不斷追求產品創新,研發多元化的綠色產品,以提升人類文明生活品質及與自然環境和諧共生。自 2009 年歐盟設立《輪胎標籤法》以提升車輛能源效率、安全及環境品質的政策後,國際中橡為此積極研發具高剛性、低滾阻、良好的抗熱老化與抗屈曲能力之新型 LH 系列碳黑,可用於一般乘用車與卡車,賦予輪胎更高的能源使用效率,以符合歐盟規範。

國際中橡在綠色產品創新研發、產品應用創新與國際環保趨勢接軌等面向持續投入,2021 年在 「產品創新」類一舉奪得第 18 屆國家品牌玉山獎 - 最佳產品類、第 18 屆國家新創獎 - 企業新創獎和 International Innovation Awards 2021 四項大獎。

「Continex LH 系列 低滾阻高耐磨碳黑」產品共獲得包含第 18 屆國家品牌玉山獎、第 18 屆國家新創獎 - 企業新創獎和 International Innovation Awards 2021 等三個獎項,此產品專為綠色輪胎設計,係採用高活性技術製成,此技術原理是在大粒徑的碳黑粒子表面增加活性點,讓碳黑與橡膠分子之間的作用,既可維持較佳分散性,擁有較低的遲滯現象,以及良好的補強性,賦予輪胎更低的滾動阻力與更加優異的耐磨特性,提升車輛的燃油經濟效率並延長輪胎的使用壽命,以滿足環保法令要求、共享經濟高里程數使用情境,及電動車輪胎所需的高負重結構特性,進而幫助車輛運輸產業逐步達到降低碳排的目標。

「低鹵含量抗熱老化碳黑-SATIN BLACK JE7750」榮獲第18屆國家品牌玉山獎-最佳產品類,產品開發是透過生產工藝優化與高結構設計,使碳黑鹵素含量降低 40~70%,與常規品級 ASTM 軟質碳黑相比,能為橡膠製品提供 7~25% 的抗熱老化性能的提升,除能夠降低汰換更新的次數與減少廢棄橡膠的產生外,亦可減少橡膠配方中的抗氧化劑與抗老化劑的投放,有效降低生產成本,並減少對於環境的衝擊。

-

International Innovation Awards 2021

-

第 18 屆國家新創獎 - 企業新創獎

-

第 18 屆國家品牌玉山獎 - 最佳產品類

Green products

Based on our professional carbon black technology, CSRC is constantly pursuing product innovation. Based on our core concepts and principles, our most important green products are “New LH Series Carbon Black” and “Non-Toxic Carbon Black Series” as well as “Environmentally Friendly Recycled Carbon Black.

New LH Series Carbon Black

CSRC is actively developing "New LH Series Carbon Black" with high rigidity, low rolling resistance, good thermal aging resistance, and buckling resistance characteristics. These features enhance tire durability and performance for manufacturers and facilitate excellent tire label performance. Through practical testing, tires manufactured using the "New LH Series Carbon Black (Continex-LH ™)" show optimized rolling resistance and improved tread wear resistance, in turn reducing vehicle fuel consumption and carbon emissions. According to EU statistics, comprehensive adoption of energy-efficient tires for vehicles across the EU could annually reduce carbon dioxide emissions by 4 million tons, equivalent to removing 1.3 million passenger cars from EU roads each year. CSRC's R&D Center in the United States has obtained relevant patents, including applications for passenger car tire treads and truck tire treads, and will initiate laboratory-scale trials.

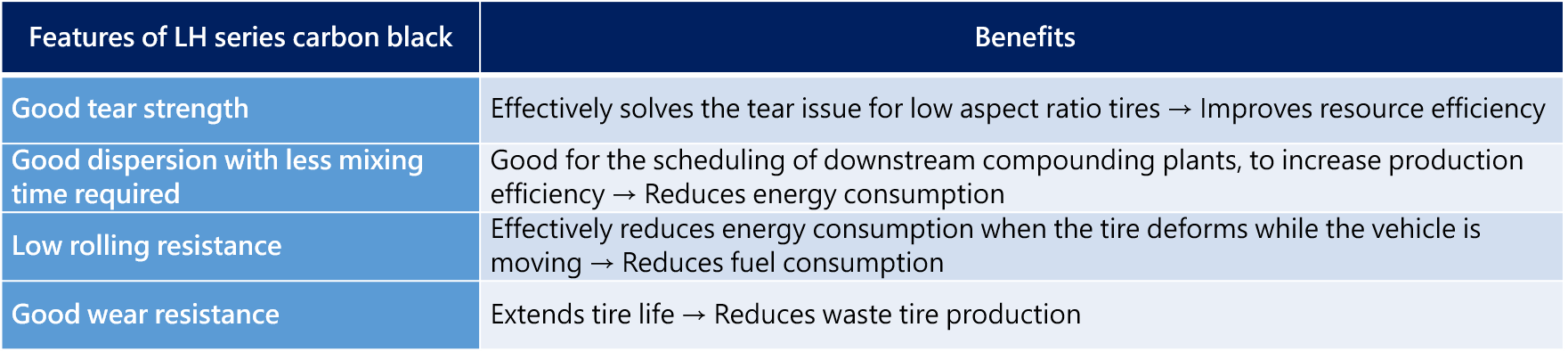

Non-Toxic Carbon Black Series

Rubber and plastic (such as ABS and PP) and transparent paints and coatings on natural materials may contain highly hazardous materials such as polycyclic aromatic hydrocarbons (PAHs). In addition, studies have shown that PAHs are most harmful to the human skin and respiratory tract. As persistent organic pollutants, they have been listed as carcinogens by the International Cancer Research Center. In view of this, we are committed to reducing the content of PAHs in carbon black, complying with the second-category requirements of German Safety (GS) standards as issued by Germany's Product Safety Commission (AfPS), and conducting annual tests for PAH limits and content in carbon black, thereby allowing customers to purchase and use our products with peace of mind. In 2023, the Linyuan Advanced Plant in Greater China passed hazardous substance testing for 233 items, achieving a 100% inspection product qualification rate.

Eco-circular Carbon Black

In response to the global net zero emissions trend, we are further introducing the "New Circular Economy Model." Starting from raw materials, we collaborate with waste tire recycling and pyrolysis plant operators to utilize recycled carbon black and pyrolysis oil. Through R&D technology adjustments in carbon black formulation and processes, we produce new “Eco-circular Carbon Black." This not only meets the tire and rubber industry's demand for sustainable raw materials, but also achieves a closed-loop system for carbon black, thereby achieving the goal of reducing carbon emissions.

The Company continues to invest in R&D to explore various sustainable/renewable materials and energy sources, optimize production processes, improve energy utilization efficiency, and produce stable high-quality "Eco-circular Carbon Black" suitable for different requirements. Through rigorous quality control, in addition to ensuring tire quality remains unaffected when using low-carbon products, advanced production and blending technologies ensure the physical properties of Eco-circular Carbon Black match those of virgin carbon black, reducing variability in tire rubber formulations. To meet customer carbon reduction goals, we collaborate with the development needs of downstream tire customers to develop products that meet circular economy requirements and achieve carbon reduction.

In response to international customers' emphasis on product environmental protection and carbon reduction, CSRC actively develops new grades of low-carbon and environmentally friendly carbon black products. The Linyuan Advanced Plant in Greater China obtained carbon black carbon footprint certification in 2022, assisting end customers in meeting green requirements.

"Ouroboros Solution" co-creates green sustainability with the industry

- CSRC collaborates with Maxxis Tires to utilize the "Ouroboros Solution" to recycle carbon black and reclaimed oil from waste tires, manufacturing environmentally friendly recycled products – CONTINEX SC series carbon black, supplying Maxxis Tires for low-carbon, eco-friendly bicycle tire production. The CONTINEX SC series not only reduces carbon emissions but also stabilizes quality, reducing variability in tire production formulations and minimizing resource consumption for development and production due to formula changes. It meets the dual requirements of sustainability materials and stable quality in the tire and rubber industries.

-

產品品質

我們以「全員參與,客戶至上」為品質政策,以國際環保標準建立品質管理系統,確保產品優良品質。此外,我們每年亦鼓勵同仁積極參與國際研討會議,內容包含國外最新生產技術、污染防治技術與設備之發展等,獲取國內外市場資訊與行業發展方向,再回各廠與同仁分享,並透過全球八廠品保實驗室之技術交流,整合相關資源,將資源利用極大化。

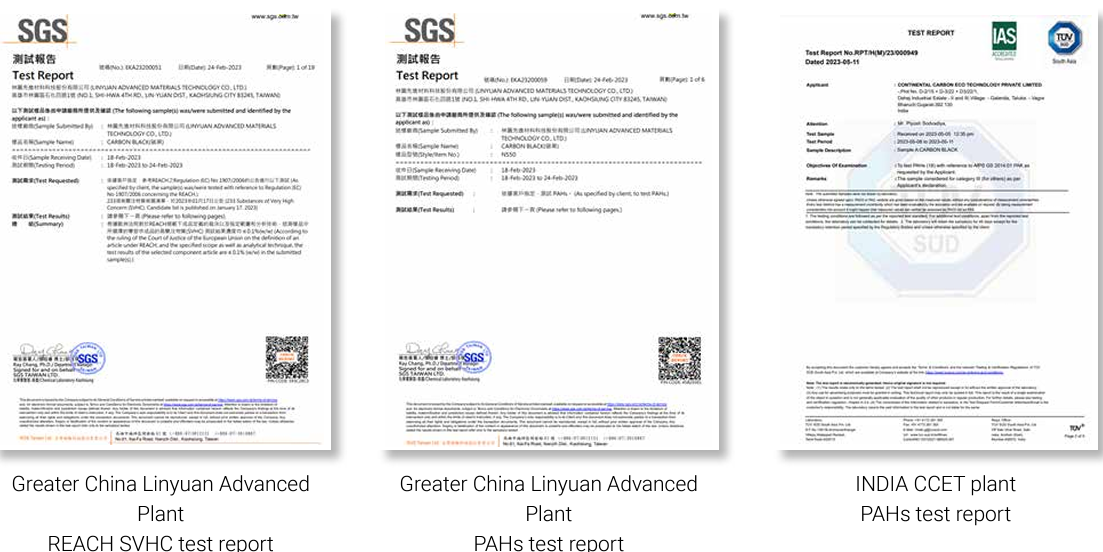

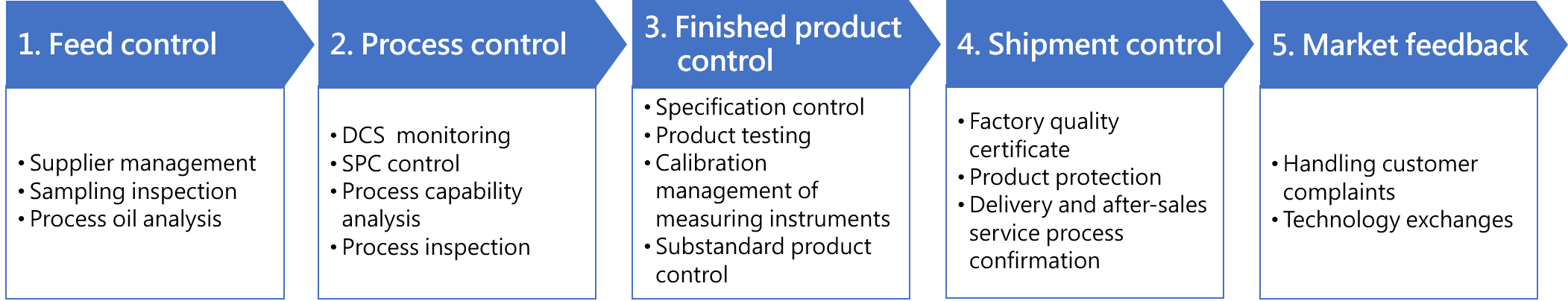

國際中橡制定品質管理辦法,以客戶需求為考量,並以達成客戶滿意度 100% 為目標,透過系統化的品質管理流程,確保產品品質管控作業的一致性,同時以 5 階段品管模式,將各階段作業項目詳列出來,有效確保產品品質,讓品質管理系統的執行與改進有所依循。

除了內部的產品管理,我們也持續通過外部第三方檢測。林園與大陸三廠通過 IATF 16949:2016 版汽車產業品質管理系統驗證 與 ISO 9001:2015 版品質管理系統驗證 ,以確保系統化之改善管理落實執行。

-

林園先進材料科技ISO-9001有效期限 : 2024/12/09ISO-9001有效期限 : 2024/12/09IATF-16949有效期限 : 2023/11/05IATF-16949有效期限 : 2023/11/05

-

中橡 (馬鞍山) 化學工業ISO-9001有效期限 : 2024/02/07ISO-9001有效期限 : 2024/02/07IATF-16949有效期限 : 2024/02/07IATF-16949有效期限 : 2024/02/07

-

中橡 (鞍山) 化學工業ISO-9001有效期限 : 2024/09/07ISO-9001有效期限 : 2024/09/07IATF-16949有效期限 : 2024/09/07IATF-16949有效期限 : 2024/09/07

-

中橡 (重慶) 炭黑ISO-9001有效期限 : 2024/03/11ISO-9001有效期限 : 2024/03/11IATF-16949有效期限 : 2024/03/11IATF-16949有效期限 : 2024/03/11

Product quality

CSRC is committed to meeting customer needs, adopting an organized quality management process, and implementing a "Five-Stage Quality Control Model" that details operational items at each stage. This approach effectively ensures product quality consistency. Through this "Quality Management System," we ensure strict implementation of quality management across departments and conduct checks on compliance with packaging regulations. For products requiring special specifications, we adopt a manual review process, requiring approval from the Quality Assurance Supervisor, Plant Manager, Technical Department Manager, and Business Department Manager, ensuring delivery to customers only after meeting standards. This series of measures ensures the stability and reliability of product quality, supporting continuous improvement and implementation of the quality management system. To enhance product control and customer trust, some suppliers visit the plant site annually for secondparty audits. Each plant obtains relevant external third-party testing for product quality management, such as IATF 16949:2016 automotive quality management system certification and ISO 9001:2015 quality management system certification.

全球指標性碳黑製造商國際中橡集團,獲綠色實踐殊榮!

因應全球循環經濟趨勢與綠色產品的重視,國際中橡集團碳黑事業 (Continental Carbon) 除致力於碳黑產品綠色創新與節能應用的研發,更持續實踐企業永續發展及環境保護,將企業社會責任發展落實營運,由於國際中橡在產品創新與循環經濟的長期投入與實踐,旗下林園先進材料科技股份有限公司在 2020 年榮獲「亞洲企業社會責任獎 (AREA) - 綠色領導獎」的表彰之外,國際中橡集團在 2021 年獲得亞洲最具領導聲望與永續性的獎項,包含:The Asia Corporate Excellence & Sustainability Awards (ACES) 2021 - Top Green Companies in Asia、2021 TCSA - 台灣永續企業績優獎與永續報告傳統製造業金獎、2021 TSAA 台灣永續行動獎,榮獲國際永續性企業多項大獎一致肯定。

-

亞洲企業社會責任獎 (AREA) - 綠色領導獎

-

ACES 2021 - Top Green Companies in Asia

-

2021 TCSA - 台灣永續企業績優獎與永續報告傳統製造業金獎、2021 TSAA 台灣永續行動獎

-

The 19th National Brand Yushan Award – Outstanding Enterprise Category

-

2022 TCSA Taiwan Corporate Sustainability Award - Taiwan's Top 100 Sustainability Model Enterprises Award

-

2022 TCSA Gold Level of Sustainability Report.

CSRC - Continental Carbon, a global indicator of carbon black manufacturer, wins Green Practice Award!

CSRC Group's carbon black segment (Continental Carbon) has been contributing to the world's increasing attention for circular economy and green products by exploring green, innovative, and energy-saving uses of carbon black, and adopting sustainable and environment-friendly practices and enforcing corporate social responsibilities in all aspects of business operation.

Owing to CSRC Group's long-term commitment to product innovation and circular economy. CSRC Group was recognized in several prestigious sustainability awards.

Linyuan Advanced Materials Technology Co., Ltd. won the 2020 Asia Responsible Enterprise Awards (AREA) – Green Leadership.

-

The Asia Corporate Excellence & Sustainability Awards (ACES) 2021 - Top Green Companies in Asia;

-

2021 TCSA - Best Sustainability Performance

-

2021 Taiwan Sustainability Action Award (TSAA)

-

The 19th National Brand Yushan Award – Outstanding Enterprise Category

-

2022 TCSA Taiwan Corporate Sustainability Award - Taiwan's Top 100 Sustainability Model Enterprises Award

-

2022 TCSA Gold Level of Sustainability Report