綠色營運

環境政策

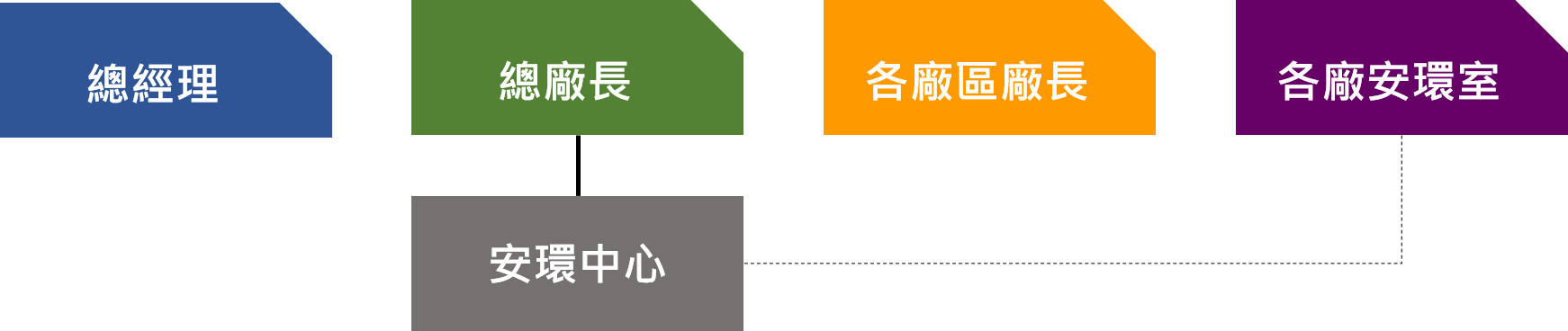

國際中橡深知地球資源有限,因此環境保護一直以來是我們極重視之面向,除透過循環經濟找出經濟與環境的平衡點、善盡資源使用外,國際中橡亦秉持關懷環境、珍惜資源的精神,制定「與環境和諧共生、為社會永續經營」的環境經營理念,並於國際中橡碳黑事業群設有安環中心,推動碳黑各廠之環境、工安、勞工人權等執行方案,並統籌主要環境政策方向,再由各廠安環室依照政策並執行環境管理方案。每季定期檢討,並向總廠長、總經理報告。

安環中心職責

- EHS 政策制訂﹑關鍵指標 (KPIs) 目標訂定﹑標準培訓﹑推動電子化管理系統建置新標準研究與導入。

- EHS 法規釋義及標準化推動、重大風險監控。

- EHS 變更管理政策及技術標準制訂。

環境管理系統

自 1997 年因應國際化環保要求,台灣林園廠即導入 ISO 14001 環境管理系統,並取得 ISO 14064-1 溫室氣體盤查標準的國際標準認證;大陸地區各廠也導入 ISO 14001 管理系統,同時每年通過當地質量認證中心監督審核,提升國際中橡在節能、環保、生產製程的管理品質,和改善方案規劃的依循方向,落實國際中橡環境保護政策與降低環境衝擊影響。對於原料、製程與產品均秉持關懷環境、珍惜資源為最高管理原則。

-

林園先進材料科技ISO-14001有效期限 : 2024/08/29ISO-14001有效期限 : 2024/08/29

-

中橡 (馬鞍山) 化學工業ISO-14001有效期限 : 2024/01/25ISO-14001有效期限 : 2024/01/25

-

中橡 (鞍山) 化學工業ISO-14001有效期限 : 2022/10/08ISO-14001有效期限 : 2022/10/08

-

中橡 (重慶) 炭黑ISO-14001有效期限 : 2024/01/27ISO-14001有效期限 : 2024/01/27

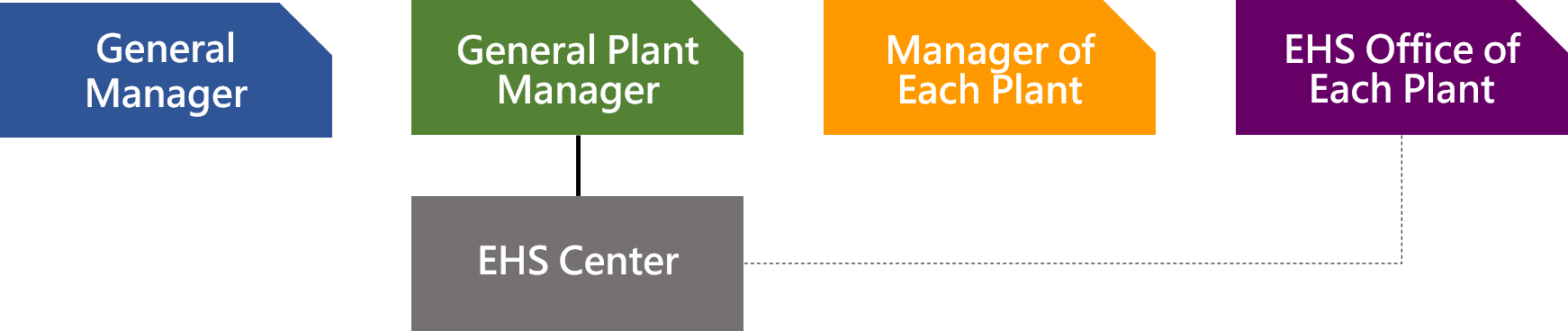

In climate governance, the Board of Directors serves as the Group’s top climate change governance body, which oversees the Group's climate change strategies and approaches. The Corporate Sustainability Committee has established the Sustainable Environment and Products Team that is operating across plants and units. It is responsible for planning and formulating carbon reduction, greenhouse gas emission, and climate change impact management and mitigation tasks.

We identify relevant climate change risks and opportunities through each operating plant and department, develop countermeasures, and report the identification results to the Corporate Sustainability Committee on a regular basis. The Corporate Sustainability Committee formulates control measures and action plans for various climate change-related risks and opportunities, adjusts and identifies climate change factors in a timely manner, and assigns each committee working group to implement control and action plans in accordance with the environmental policies.

The Corporate Sustainability Committee regularly reports the core climate risks and opportunities faced by CSRC, countermeasures, and the implementation results to the Board of Directors per year, so that the board can keep abreast of the climate-related risks and opportunities, decide on the relevant management policies, and supervise the implementation.

-

Linyuan Advanced Materials Technology Co., Ltd.ISO-14001Expiry date : 2027/07/23ISO-50001:2018Expiry date : 2026/01/10

-

CSRC China (Maanshan) CorporationISO-14001Expiry date : 2027/01/25

-

CSRC China (Anshan) CorporationISO-14001Expiry date : 2025/10/08

-

CSRC China (Chongqing) CorporationISO-14001Expiry date : 2027/01/27

-

Continental Carbon Eco Technology Private LimitedISO-14001Expiry date : 2026/03/08

-

Continental Carbon India Private LimitedISO-14001Expiry date : 2027/03/09

溫室氣體管理

國際中橡重視溫室氣體管控,其中林園廠每年通過第三方盤查溫室氣體排放,取得 ISO 14064-1 溫室氣體查證聲明書,並以盤查結果作為內部溫室氣體管理依據,釐清生產設備運作效能與作業流程效益,進而做適時調整。為響應氣候風險因應,管理層隨時注意環保署溫室氣體相關法規要求,嚴守規定,並且因林園廠為環保署公告應申報溫室氣體排放量的第二批排放源,所以盤查結果除作為後續推動溫室氣體管理之參考,亦定期於溫室氣體登錄平台申報。

林園廠溫室氣體排放統計

| 排放範疇 | 2019 | 2020 | 2021 |

|---|---|---|---|

| 範疇一 (噸CO2e) | 202,107 | 245,245 | 250,642 |

| 範疇二 (噸CO2e) | 14,402 | 11,485 | 7,392 |

| 總排放量 (噸CO2e) | 216,509 | 256,730 | 258,034 |

| 排放密集度 (噸CO2e/噸) | 2.27 | 2.69 | 2.47 |

- 溫室氣體排放計算採營運控制權法進行盤查,計算方法為活動數據*排放係數*GWP值 (排放係數值引用環保署溫室氣體排放係數管理表107年度版,GWP值係引用IPCC第四次評估報告(2007)),溫室氣體包含二氧化碳、甲烷、氧化亞氮、氫氟碳化物、全氟碳化碳、六氟化硫、三氟化氮。

- 在接受第三方溫室氣體查證時 2019 年之電力碳排係數還未公布,因此查證當下以 2018 年度排放係數 0.533kg CO2e/度進行計算。

- 範疇一排放源包含廢氣、重油、乙炔、柴油、車用汽油、水肥、液化石油氣。

Greenhouse gas management

In the face of global climate change, CSRC is constantly strengthening the Group's climate adaptation and resilience and mitigating greenhouse gas emissions. CSRC conducts a greenhouse gas inventory every year and formulates a greenhouse gas management policy based on the inventory results and then sets reduction targets and draws up measures, while replacing traditional energy with low-emission one to reduce carbon emissions from the process and planning to gradually adopt carbon capture technology. In this regard, we have set the group-wide long-term carbon reduction target for 2030 based on the greenhouse gas emissions and management status of each operating plant, to reduce emissions by 21% compared to the baseline year of 2018. In 2023, the achievement rate was 100%.

In order to effectively achieve the goal of greenhouse gas reduction, the Group has established an Emissions Management Team consisting of personnel from the Technical Department, the Safety and Environment Center, and various operating plants. A cross-plant online e-carbon emission monitoring system has been established for plants in Greater China, which can be checked at any time. Regarding carbon emissions, plants in all regions around the world hold regular meetings to review and track carbon emissions and invite each plant to share its carbon reduction solutions and performance with other plants so that they can learn from each other. The monthly and quarterly greenhouse gas emission intensity of the plants in Greater China has been listed as a KPI of the plants. The KPI is linked to the performance bonus to motivate all employees to work together for energy conservation and emission reduction.

To realize the concept of environmental sustainability, CSRC has invested in various environmental protection projects in recent years, including desulfurization and denitrification systems and low-nitrogen burners and has successively built natural gas pipelines in Greater China to replace heavy crude oil as fuel, to reduce carbon emissions. To further promote low-carbon transition, the Group has budgeted greenhouse gas management and regularly reports to the Board of Directors.

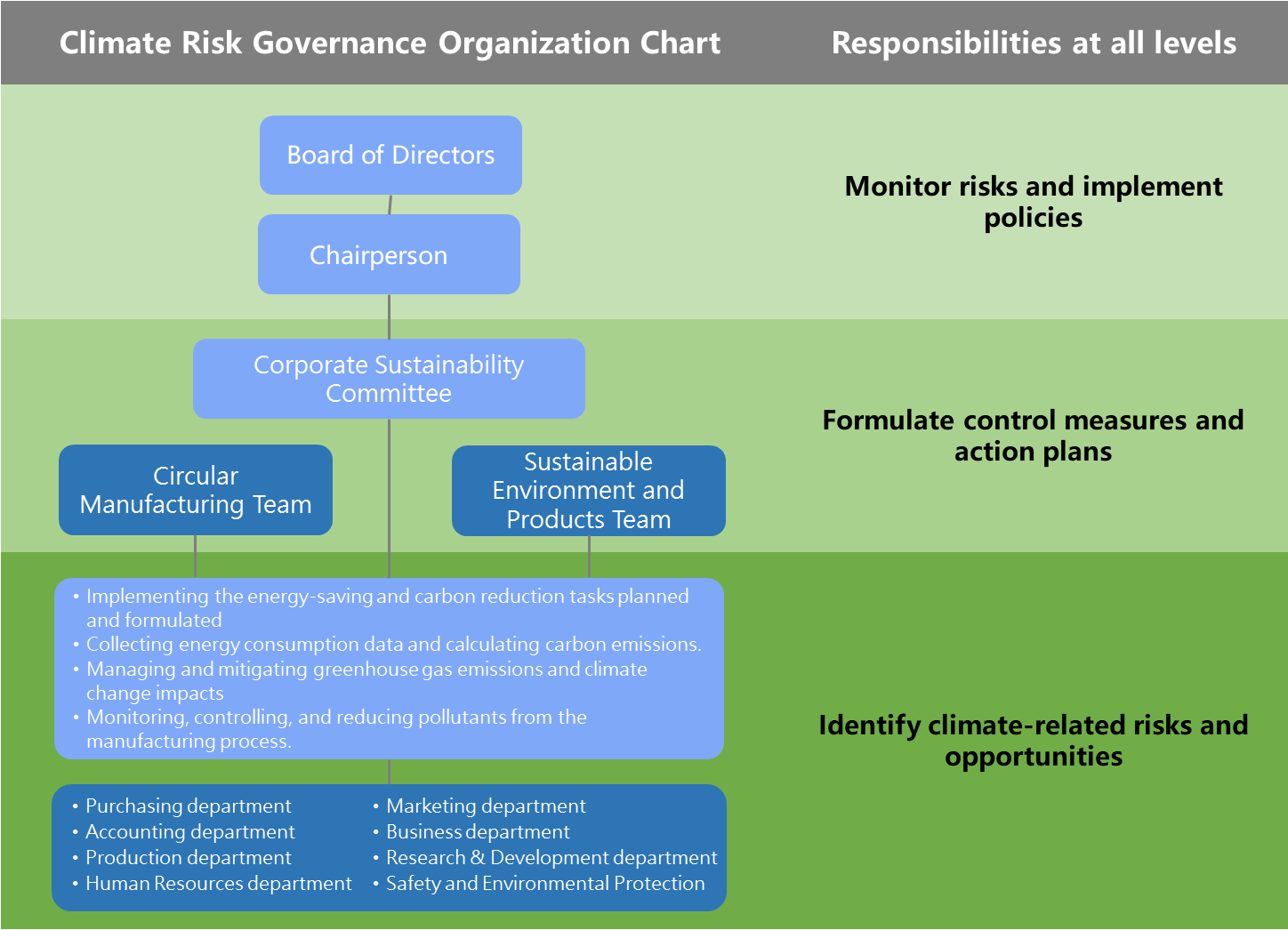

Roadmap for low-carbon transition of CSRC

Note 1: The Group’s baseline year is adjusted to 2018 to align with the inclusion of the plants in the United States and India in the scope.

Note 2: The Scopes 1 and 2 emissions of all production sites are included in this report.

Note 3: The reason for the higher target by 2025 compared with the baseline year is that the CCET plant in India was built in 2023, and the future production capacity is expected to increase by 5% compared to the baseline year.

| item | 2018 | 2021 | 2022 | 2023 |

|---|---|---|---|---|

| Total greenhouse gas emissions (tCO2e) | 1,317,579 | 1,200,938 | 1,068,501 | 1,017,377 |

| Greenhouse gas emission intensity (tCO2e/t) | 2.66 | 2.70 | 2.85 | 2.92 |

Energy management

CSRC's energy management is divided into two major directions: energy structure management and energy efficiency improvement. Energy structure management is mainly adjusted toward a circular economy model; for example, the process waste gas recycled is converted into steam to generate electricity for self-use or sale; the construction of a solar power system to increase the generation of renewable energy; and biomass fuel is used to reduce greenhouse gas emissions. Enhancement of energy efficiency aims to improve the electricity efficiency of equipment or reuse thermal energy to maximize the value; for example, the demand for purchased electricity is reduced through the recovery of thermal energy with waste heat boilers, or large equipment is regularly maintained and replaced.

In 2023, the total power generated in the relevant energy-saving programs in the energy structure management by all operating plants of CSRC exceeded 131,212 kWh, including 911,000 kWh of renewable energy. Among the energy-saving solutions for improving energy efficiency, the use of waste heat boilers to recover thermal energy reduced electricity consumption by a total of 1,305 kWh, equivalent to a reduction of greenhouse gas emissions by 901.94 metric tons of CO2e.

Each operating plant will continue to improve its energy management capabilities. In 2023, we began to systematically assess the replacement of fuel oil with natural gas and recycled oil and planned to increase steam and electricity production to effectively reduce greenhouse gas emissions by gradually replacing fuel oil with high-emissions. It is estimated that about 13,469 metric tons of CO2e can be reduced.

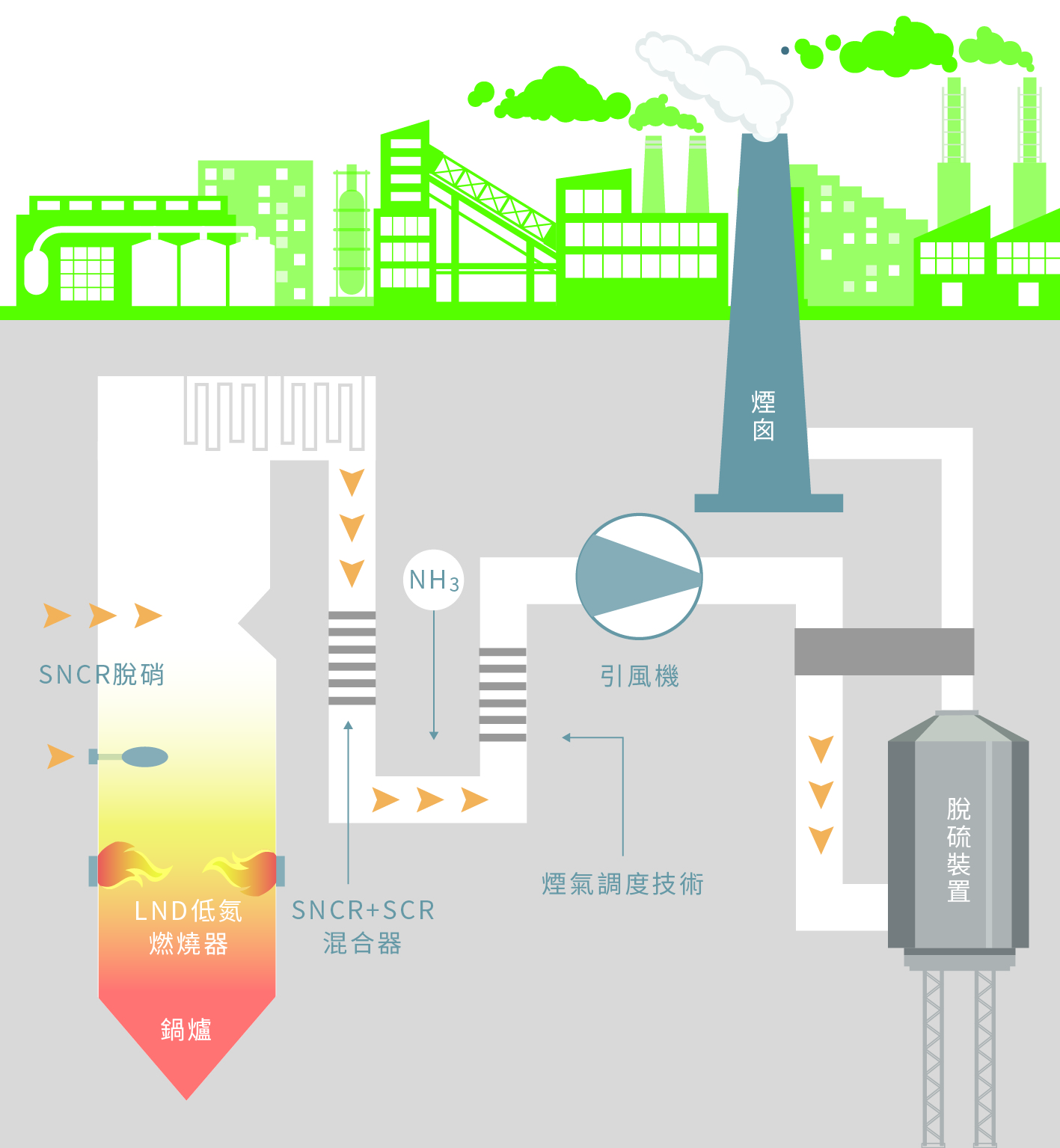

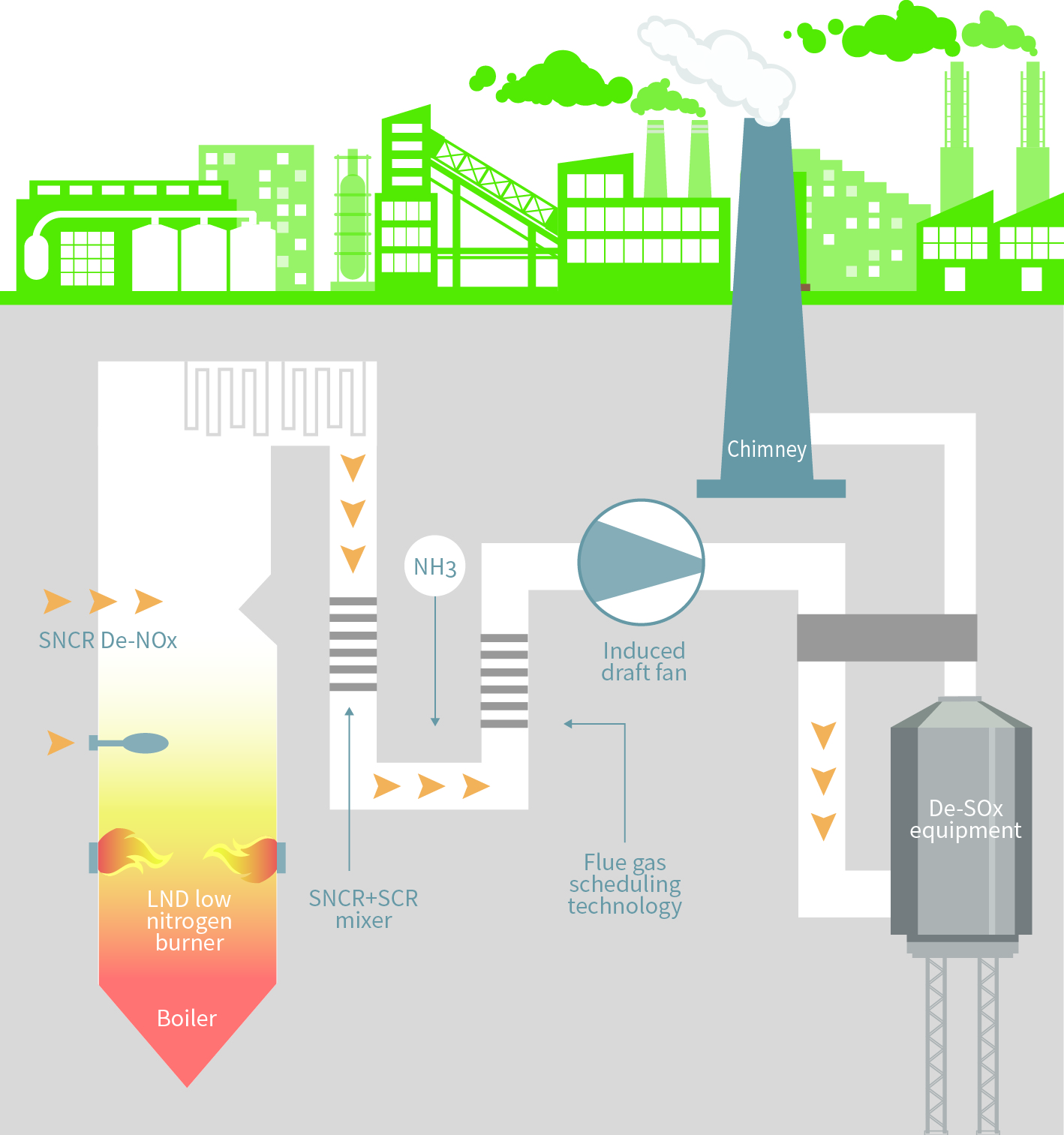

空氣污染管制

碳黑生產過程使用的原料油經反應器燃燒熱裂解及相關化學反應後,主要產生的空氣污染物有揮發性有機物 (VOCs)、硫氧化物 (SOx)、氮氧化物 (NOx)、粒狀污染物 (總懸浮微粒 TSP)。為減少環境衝擊,我們隨時監控氣體排放數據作為管理依據,並積極佈署空污減量措施。

揮發性有機物 (VOCs) 防制

為控制原料油槽的揮發性有機物,國際中橡在各貯槽上方安裝油氣收集系統,在呼吸閥設置連接管,利用動力風車抽風,使槽內維持微負壓,再將抽取的廢氣導入燃燒爐空氣使用,達到防制效果。

硫氧化物 (SOx) 防制

碳黑製程會使用煤焦油、原油裂解塔底油 (FCC),然而,煤焦油含硫量約為 0.3-0.5%,FCC 油品含硫量則高達 2-4%,均高於目前油品含硫量標準,因此需經過脫硫處理才能達到空氣污染物 SOx 排放濃度標準。為此,林園廠於安裝 De-SOx 脫硫設備於工廠煙囪之排放管道,成功將每月 SOx 平均排放濃度由 160 ppm 降至 22 ppm 以下,搭配低逸散設施,盡可能降低空氣品質的負荷量。

氮氧化物 (NOx) 防制

目前採用的減少氮氧化物 (NOx) 方法有:

- 煙氣回流分段燃燒:將煙氣分成三段燃燒,第一階段將部分煙氣回流至鍋爐燃燒區,供給小於完全燃燒的空氣量,達到稀釋氧氣濃度使燃料中的氮無法生成 NOx。第二及第三階段則進行殘餘的燃料與空氣燃燒,因為其燃燒速度較慢,可降低火焰溫度,同樣形成低氧濃度環境,減少 NOx 生成。

- 選擇性觸媒還原法 (Selective Catalytic Reduction, SCR) 脫硝系統:為目前最普遍且脫硝效率最高之技術,效率可達 90% 以上 (以環保局 NOx 排放濃度 30 ppm 計算),成功解決林園廠鍋爐尾氣產生之煙道氮氧化物排放問題。

粒狀污染物 (總懸浮微粒 TSP) 防制

廠區持續改善生產設備以減少污染物產生,如針對袋式集塵器進行濾煙袋提前更新,及研發圓形脈衝清洗式袋式集塵器,對粒狀污染物防制可達 99% 以上之集塵效率。此外,導入 PDA 巡檢系統,能隨時掌握生產狀況並即時調整,有效解決原設計的袋式集塵器易堵塞積碳、漏煙等缺失。

用水管理

我們嚴格控管水資源使用情況並持續提升水循環使用效率,避免過度取水造成周圍環境的傷害,並且將推動水資源平衡計畫,其中包含 2020 年起與鄰近工廠合作,蒸汽銷售予鄰近工廠合作夥伴後,合作夥伴將製程產生之冷凝水,輸送回林園廠再做使用,擴大水循環影響力。

水資源使用統計

| 項目 | 2019 | 2020 | 2021 |

|---|---|---|---|

| 製程自來水用量 (m3) | 1,469,105 | 1,475,518 | 1,352,859 |

| 製程回收水用量 (m3) | 174,897 | 176,735 | 109,123 |

| 製程總用水量 (m3) | 1,644,002 | 1,652,253 | 1,461,982 |

| 製程水回收率 (%) | 12 | 12 | 8 |

| 用水密集度 (m3/噸) | 17.3 | 15.5 | 14.0 |

廢棄物處理方法

國際中橡強調廢物利用的循環經濟精神,妥善處理事業廢棄物,恪遵各項廢棄物法令要求,並尋找資源再利用的契機。我們依環保署「事業廢棄物管理作業程序」進行內部先行處理,之後委託合格的廢棄物處置承包商做後續清除工作。

廢棄物處理統計 (單位:噸)

| 處理方式 | 2019 | 2020 | 2021 |

|---|---|---|---|

| 焚化處理 | 750.16 | 646.7 | 592.1 |

| 掩埋 | 104.51 | 0 | 17.2 |

| 熱處理 | 115.86 | 109.1 | 144.9 |

| 物理處理 | 232.23 | 155.5 | 502.0 |

| Recycling (tons) | - | - | 6 |

| 合計 | 1,054.43 | 1,353.42 | 1,262.2 |

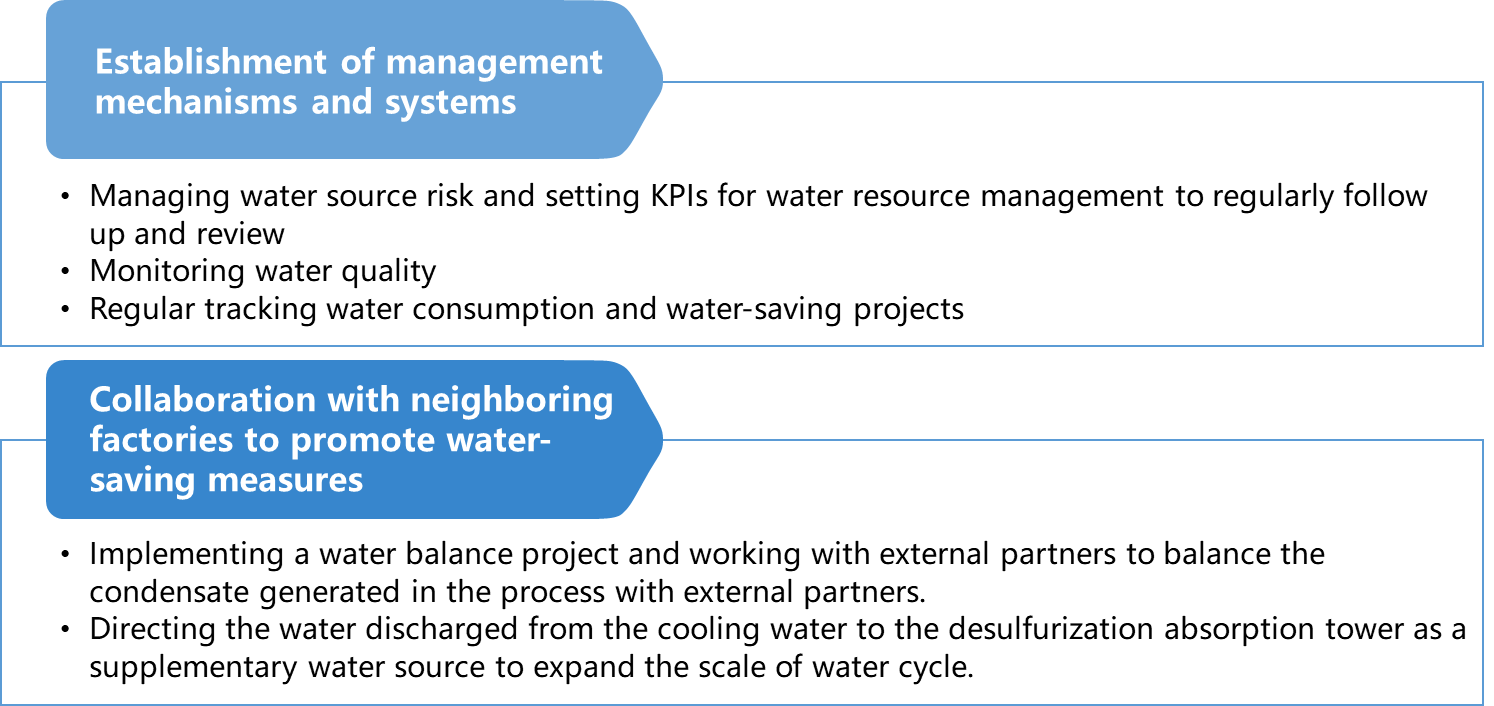

Water usage management

CSRC strictly controls the use of water resources and continues to improve the efficiency of water circulation to prevent damage to the surrounding environment caused by excessive water intake. Linyuan Advanced in Greater China and the operating plants in the United States have implemented a water balance project and continue to adjust the water resource consumption on a rolling basis. They work with neighboring factories to sell steam to neighboring factories, and the external partners transport the condensate generated in their processes back to the plants for reuse. Other internal water-saving actions include the following: diverting cooling water discharged from the cooling water to the desulfurization absorption tower as a supplementary water source, to expand the scale of water cycle; and regularly examining and repairing leaks in the plant's pipelines to reduce the risk of water waste. In 2023, we continued to take water-saving measures and reviewed the room for improvement in practical operations to achieve the best water resource use efficiency.

Water resource management methods and implementation plan of CSRC

In terms of water resources management, CSRC continues to examine the process water consumption in the plants and implements water conservation and recycling projects to make the most effective use of water resources. In 2023, the wastewater recycling rates of the group is 89%, and plants in Greater China were 56% for Linyuan Advanced, 90% for Maanshan, and 22% for Anshan; the said rates of the plants in India were 100% for CCET and 100% for CCIPL; the said rates of the plants in the United States were 100% for CCC Sunray and 100% for CCC Ponca.

Waste disposal

CSRC complies with various waste disposal laws and regulations to ensure that all waste generated is properly disposed of. In order to live up to the spirit of responsible production and circular economy, each plant has kept abreast of the source, type, and quantity of various waste resources, and ensured that their disposal methods and flows are in compliance with all environmental laws and regulations, to further achieve the goals of cleaner production, resource recycling and industrial waste reduction to achieve the goals of pollution reduction, waste reduction, and environmental protection. In 2023, the Group achieved a waste recycling rate of 80.4%, of which 87.9% in Greater China, 72.0% in India, and 51.4% in the United States. All are expected to achieve short-term targets ahead of schedule.

In 2023, the Group's total waste generated was 6,767.5 tons (Note), a significant decrease of 13% from 7,742.8 tons in 2022. In Greater China, Anshan uses incineration method to dispose of general solid waste, which has led to significant reduction of waste.